Product lines

Almost every person has already once held an aluminium aerosol can in his hand. It is most likely that those products were made on one of our production lines. Customers world-wide are convinced by our machinery and its core competences: Forming of a hollow body either by Impact Extrusion or DWI, trimming, printing, necking and shaping.

IE Production Lines

Customized production line using an impact extrusion press to form a hollow cylinder out of an aluminium slug by one stroke. The cylinder is subsequently cut to length, decorated, necked and shaped to an Aluminium Aerosol Can.

View CMC line video

CMC 200

This line is the workhorse of the industry. It is used everywhere on the planet for the production of monoblock aluminium aerosol cans with a production speed up to 200 cpm. Being available in three different diameter ranges: 20-45 mm, 35-53(59) mm and 45-66 mm, the line can be used to offer a great variety of metal packing solutions to your customers in the aerosol markets for bodycare, home care, food and technical products.

Packing machine

for strapping aluminium aerosol cans in bundles or layer blocks for pallet packing

Special features

- Ideal for aerosol cans

- Optimal grouping of cans

- Fast and gentle strapping via servo-controlled process

- Synchronous can transport from the upstream machine

- High production reliability and security

- Supplement machine to palletize the bundles are available

Postwasher

Our customized postwashing machines are equipped with a patented spraying system to ensure low water consumption.

A bypass function for the transport without washing/rinsing is included as standard.

Technical data

| Type | PWM 45 | PWM 55 | PWM 66 | PWM 80 |

|---|---|---|---|---|

| Max. Diameter (mm) | 45 | 55 | 66 | 80 |

| Chain pitch | 3 x ¾” | 4 x ¾” | 5 x ¾” | 6 x ¾” |

| Number of washing / rinsing cabins | 2 | 2 | 2 | 2 |

Special features

- Stainless steel design, cabins equipped with windows

- Washing of the cans in the first washing/rinsing cabin

- Rinsing of the cans in the following rinsing cabins

- All cabins equipped with a patented spraying system with low water consumption

- Electrically heated tank for the first washing/rinsing cabin equipped with pumps, level control and temperature regulation

- Dripping area after washing, vertically arranged pins and drying blades

- Automatic level control of the tanks, equipped with safety unit against water shortage, temperature monitoring unit

- Stainless steel tank for collecting the dripping water below the washing machine

- Drying of the cans in the gas heated oven, low-energy design

- Chain guides made of PTFE (Teflon)

- Additional blowing nozzles for drying the interior and the rim of the cans

- Reliable system for sucking off the oven exhaust air

Leak detector

A photocell is used to detect if rays of light fall into the can through micro-holes. Defective cans are automatically ejected at the outfeed conveyor after the Leak detector. A 100% quality-control ensures that only complete secure cans leave the line.

The Leak detector can be placed on the outfeed conveyor of the Necking machine. Alternatively it can be integrated as a stand-alone machine in the line.

Necking machine

The cylinder is necked and shaped by necking dies up to the final can design. Processes as threading, curling, beading, registered embossing and debossing to create unique shapes and designs fitting the needs of your customers.

Any combination to create a 56 or 80 or 84 station necker system for advanced/modified alloys or DWI are possible.

Technical data

| Type | C200.28 | C200.28.VE | C200.36XVE | C200.40VE |

|---|---|---|---|---|

| Can diameter (mm) | 35-66 | 35-66 | 35-80 | 35-66 |

| Finished product length (mm after necking) | 110 – 250 | 110 – 250 | 110-275 | 105 – 250 |

| Number of stations | 28 | 28 | 36 | 40 |

| Total stroke (mm) | 150 | 132/216/280 | 110 - 270 | 110 - 270 |

| Usable stroke (mm) | 90 | 90/143/180 | 80 - 187 | 80 - 187 |

Special features

- Pneumatic holding grippers with electronic control for can detection guarantee a constant stable position of the can

- Tool quick-change system for maximum product flexibility

- Compressed air-assisted necking to enable even complicated shapes

- Bottom forming unit included in the standard supply

- Maximum accessibility to the machine working area for easy handling and setting of the tools

- Optimized can transfer systems between conveyors and drums

- Infinitely adjustable stroke (C200.36XVE and C200./C250.40VE)

- Electronic presetting device to set lubrication cycle frequency

- Possible application of all our proprietary tools allowing wide machining possibilities

- Frequency-controlled motors for rotating tools (C200.36XVE and C200./C250.40VE)

Accumulator 3

for accumulating the cans and compensating the asynchronous operation of decoration unit and necking machine.

Special features

- Two-part welded frame, mounted onto the floor with a capacity of 2000 cans

- Constant chain tension system

- Safety covering of the accumulator up to a height of 2,5 m with acrylic glass panes at the front side, rear and top with sheet metal covering. A complete covering of the accumulator is optionally available

Overvarnish lacquering machine

The overvarnish is applied to protect the decoration. According to the request of your customers also special effects like matt, semi matt, gloss or haptic can be provided.

Special features

- Can transfer from the conveyor chain to a mechanical take-off drum with size-independent vacuum pockets

- Mechanical indexing gear unit with 12 stations

- Mandrel quick change unit and monitoring of the correct clamping

- Infinitely variable mandrel drive by means of controlled servomotor

- Vacuum-assisted loading and steadying of the cans on the mandrels, before and during processing

- Three roller base-coating unit designed as V-type-coating unit

- Transfer unit with take-off control and two suction units for transporting the cans from the mandrels onto the chain pins

- Oven chamber with integrated chain guide

- Sprocket bearings with re-lubricating facility, installed outside the oven in an aluminium casing sealed towards the rear wall of the oven

- Possibility of can sampling for test purposes from the pins of the dryer chain, after drying of the clear varnish.

Printing machine

The printing unit, which can apply up to 9 colours, ensures the widest possible decoration variety for monoblock cans

Special features

- Can transfer from the conveyor chain to a mechanical take-off drum with size-independent vacuum pockets

- Mechanical indexing gear unit with 12 stations

- Mandrel quick change unit and monitoring of the correct clamping

- Infinitely variable mandrel drive by means of controlled servomotor

- Vacuum-assisted loading and steadying of the cans on the mandrels, before and during processing

- Printing unit with up to 9 colours

- Transfer unit with take-off control and two suction units for transporting the cans from the mandrels onto the chain pins

- Oven chamber with integrated chain guide

- Sprocket bearings with re-lubricating facility, installed outside the oven in an aluminium casing sealed towards the rear wall of the oven

- Possibility of can sampling for test purposes from the pins of the dryer chain, after drying of the printing inks.

Basecoat lacquering machine

The cylinder receives the base coat which is important for the stain resistance and excellent print quality. The base coat is dried in the first oven chamber of the decoration drying oven.

Special features

- Can transfer from the conveyor chain to a mechanical take-off drum with size-independent vacuum pockets

- Mechanical indexing gear unit with 12 stations

- Mandrel quick change unit and monitoring of the correct clamping

- Infinitely variable mandrel drive by means of controlled servomotor

- Vacuum-assisted loading and steadying of the cans on the mandrels, before and during processing

- Three roller base-coating unit designed as V-type-coating unit

- Transfer unit with take-off control and two suction units for transporting the cans from the mandrels onto the chain pins

- Oven chamber with integrated chain guide

- Sprocket bearings with re-lubricating facility, installed outside the oven in an aluminium casing sealed towards the rear wall of the oven

- Possibility of can sampling for test purposes from the pins of the dryer chain, after drying of the basecoat

Accumulator 2

for accumulating the cans and compensating the asynchronous operation of internal coating machine and decoration unit.

Special features

- Four-part welded frame, mounted onto the floor with a capacity of 3250 cans

- Constant chain tension system

- Safety covering of the accumulator up to a height of 2,5 m with acrylic glass panes at the front side, rear and top with sheet metal covering. A complete covering of the accumulator is optionally available

Internal coat dryer

for polymerizing the internal lacquer coat, electrically heated or alternatively by gas.

Special features

- 1,2 or 3 row transport chain with baskets

- Reduced wear-out of the transport chain and the chain wheels by cardan-based drive system

- Chain tension with weight, electronically monitored

- Easy accessibility to the dryer interior due to large doors

- Quadruple door look

- Isolated doors with special door hinges for synchronized door closing

- Large outer doors with smooth surface on the oven’s front and rear sides

- Quick and easy removal and reassembly of the shafts and chain wheels in case of service

Internal coating machine

A functional lacquer is applied to seal the inside of the cylinder using moveable spray lances. In the following oven with its cooling zone the inside lacquer is cured and hardened.

Special features

- Low vibration due to solid mechanical design

- Individual vacuum circuit for machine infeed and outfeed

- Increased user comfort by direct electro-pneumatic control of the spray guns by HMI

- Shorter cleaning times by optimized exhaust performance

- Height adjustable and horizontally moveable control panel

- Combinations with different internal coating drier options (1,2 or 3 rows)

Accumulator 1

for accumulating the cans and compensating the asynchronous operation of the washing machine and internal coating machine.

Special features

- Three-part welded frame, mounted onto the floor with a capacity of 2000 cans

- Constant chain tension system

- Connecting traverse at accumulator outfeed to bridge a walkway

- Safety covering of the accumulator up to a height of 2,5 m with acrylic glass panes at the front side, rear and top with sheet metal covering. A complete covering of the accumulator is optionally available

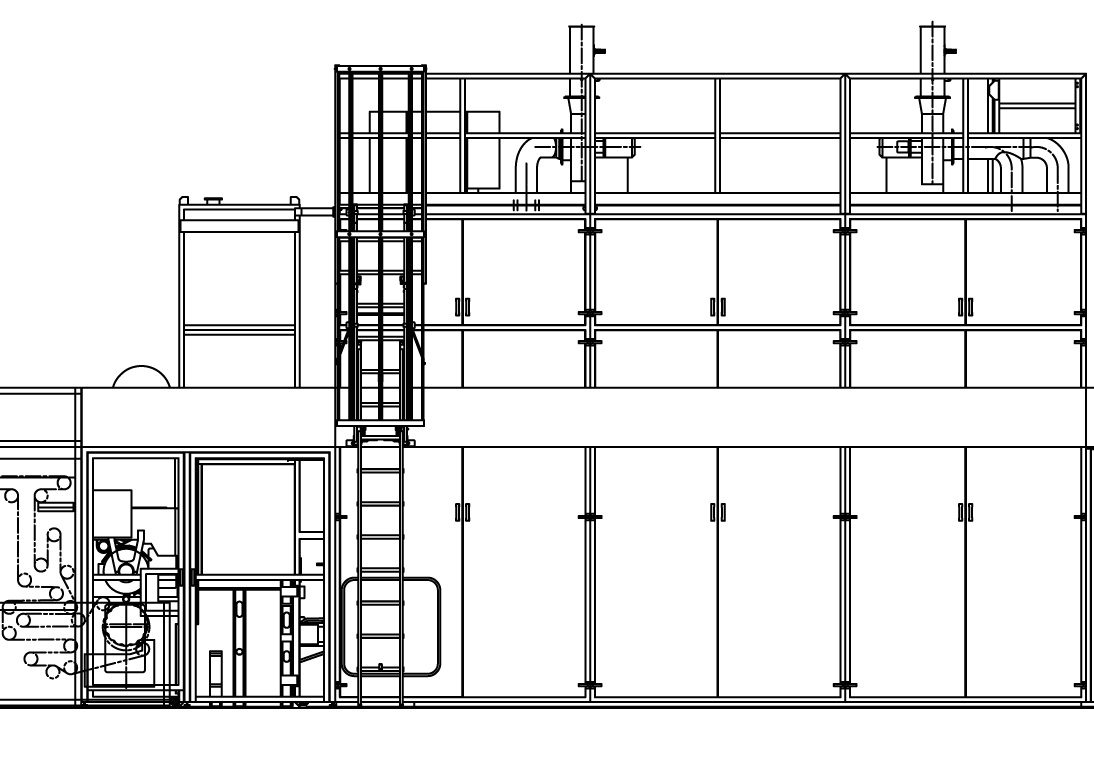

Washing machine

After pressing and trimming it is necessary to wash the lubricants from the cylinders. With our space-saving washing machines, designed in stainless steel, we offer an economic and energy-saving technology for a perfect washing result. Different machine types and a lot of special features allow as much customization as possible.

Technical data

| Type | CWM 45-5+ | CWM 55-5+ | CWM 66-5+ |

|---|---|---|---|

| Diameter range (mm) | 20-45 | 35-55 | 45-66 |

| Chain pitch | 3 x ¾” | 4 x ¾” | 5 x ¾” |

| Number of washing / rinsing cabins | 5 | 5 | 5 |

Special features

- Compact, space-saving stainless steel design, washing and rinsing cabins equipped with windows

- Reliable, adaptable infeed and outfeed system ensuring easy connection to the upstream and downstream machines

- Safe and reliable infeed and outfeed transfer through vacuum drums

- Gas or electrically heated stainless-steel drying oven with long dwell time and minimum energy consumption

- Newly designed jet spray system

- Detergent dosing by means of conductivity metering and dosing pump

- Dripping area between wet and dry zone, vertically arranged pins

- Electrically heated tanks for the degreasing cabins equipped with pumps, level control and temperature control

- Automatic level control of the tanks, equipped with a safety unit against water shortage and temperature monitoring unit

- Stainless steel tanks for collecting the dripping water below the machine

- Reliable system for sucking off the oven exhaust air

- New extra platform on top of the washing cabins for a better accessibility of the dryer

Trimming machine

The high-performance trimming machines, designed for trimming aluminium preforms to length and for brushing the body, have been fully equipped to allow flawless integration into automatic production lines. When designing the machine, particular importance was attached to ease of operation, quick tool change, easy access, solid process technology, high operational safety and little maintenance.

Technical data

| Type | MHB | MHB-G | SBB | SBM (without brushing) |

|---|---|---|---|---|

| Can diameter (mm) | 35-66 | 35-80 | 22-66 | 22-66 |

| Max. extruded overall length (mm) | 275 | 295 | 285 | 285 |

| Max. trimmed can length(mm) | 260 | 280 | 270 | 270 |

| Assumed wall thickness of cans (mm) | 0,2 - 0,6 | 0,2 - 1,0 | 0,35 - 0,8 | 0,35 - 0,8 |

Special features:

- Fully accessible from the front (MHB series), perfect control of all movements, easy change of the brush

- Centralized lubricating system

- The trimming system produces burrless cuts and guarantees a long tool life, precision adjustment in both axial and radial direction

- Mandrel quick-change systems

- Can scrap will be shredded into small pieces for easy suckoff

- Equipment for the separation and safe discharge of the trimming scrap

- Size parts are immediately located in the correct position

- The drum-type transfer unit makes sure the cans are safely transferred to the downstream equipment

- Continuously operating conveyor chain at the transfer station (MHB series)

- Deactivation of the oscillating movement of the grinding wheels possible (MHB)

- Automatic and smooth brush cleaning unit with adjustable cleaning cycle and use of commercial grinding wheels (MHB)

- Newly designed compact brushing unit for improved ergonomics, easier changeovers and maintenance (MHB)

Ironing machine

The cylinder wall thickness is optimized and the bottom is formed. This leads to constant geometrical features and light weight cans.

Special features

- Transfer of the cans from the outfeed conveyor of the impact extrusion press to the tray-type conveyor of the ironing press

- Punches with two punch holders

- Ironing rings and stripper exchangeable from above

- Pneumatically operated bottom forming unit with two dies, swing-off type

- Quick lock for facilitating punch and die exchange

- Electrical punch heating for temperature control of the punches

- Transfer of the cans to the synchronous transfer of the trimming machine

Press

If flexibility is required when producing a monoblock aluminium container, an Impact Extrusion Press is the first choice. A high performance toggle lever system produces aluminium cans with one stroke out of a slug. As a market leader, our presses are used all over the world for the production of monoblock aerosol cans.

Technical data

| Type | CP35 | CP55 | CP65 | CP75 | CP85 | Express 6000 |

|---|---|---|---|---|---|---|

| Can diameter (mm) | 10-30 | 19-45 | 25-45 | 25-53 | 35-66 | 43-80 |

| Max. extruded can length (mm) | 130 | 170 | 200 | 225 | 275 | 310 |

| Approx. wall thickness (mm) | 0,3 | 0,3 | 0,4 | 0,5 | 0,5 | 1,0 |

| Nominal press force (kN) | 800 | 1.400 | 1.600 | 2.500 | 4.000 | 6.000 |

Special features

- Sturdy frame, separate from the drive housing, for absorbing the extrusion loads; both parts made of spheroidal graphite iron

- Compact drive of the crankshaft via pneumatically controlled clutch-brake unit with spring loaded disc brake to allow controlled or immediate stops

- Speed-variable drive, creeping speed and facility for switching to reverse motion to facilitate the setting of the tooling

- Electromotive punch adjustment for correcting the bottom thickness during production

- Swing-off type slug feed and stripper frame of the take-off unit, resulting in short set-up times and simple size-part changes, optimized for high speed production

- Automatic permanent circulatory lubrication system with filter and offline filter system

- Take-off unit operating in absolute synchronism with the outfeed conveyor, ensuring trouble-free transfer of the products even in case of short extrusions and maximum stroke rates

- Inclined slug conveyor for direct feed of flat and domed slugs to the die

- Continuous rotary slug infeed system

Slug infeed

In the sorting and feeding unit the slugs are separated, aligned and fed into the extrusion press.

The processing of flat or domed slugs is possible.

Special features

- Storage container with inner lining to avoid damaged slugs

- Level control of the container by means of ultrasonic sensor

- Plate type conveyor belt

- Possibility to regulate the speed of the conveyor belt for different slug sizes

- Feed chute to the clamping-type elevator

- Clamping-type slug elevator, with overload protection at the transfer of the feed chute

Slug lubrication

The aluminium slugs are lubricated and transported to the sorting and feeding unit.

Special features

- Storage bin for storing slugs for one lubricating process

- Feeding of slugs to the lubricating barrel by means of conveyor belt

- Abrasion-proof lining of the barrel body with cover

- Manually assisted cover lifting device, monitored by limit switches

- Elevator-type conveyor belt for transporting the slugs

CMC 160

If speed 160 cpm is sufficient for you this line offers the best price-performance ratio. In order to offer a great variety of metal packing solutions to your customers in the aerosol markets for bodycare, home care, food and technical products this line is available in three different diameter ranges: 20-45 mm, 35-53(59) mm and 45-66 mm.

Packing machine

for strapping aluminium aerosol cans in bundles or layer blocks for pallet packing

Special features

- Ideal for aerosol cans

- Optimal grouping of cans

- Fast and gentle strapping via servo-controlled process

- Synchronous can transport from the upstream machine

- High production reliability and security

- Supplement machine to palletize the bundles are available

Postwasher

Our customized postwashing machines are equipped with a patented spraying system to ensure low water consumption.

A bypass function for the transport without washing/rinsing is included as standard.

Technical data

| Type | PWM 45 | PWM 55 | PWM 66 | PWM 80 |

|---|---|---|---|---|

| Max. Diameter (mm) | 45 | 55 | 66 | 80 |

| Chain pitch | 3 x ¾” | 4 x ¾” | 5 x ¾” | 6 x ¾” |

| Number of washing / rinsing cabins | 2 | 2 | 2 | 2 |

Special features

- Stainless steel design, cabins equipped with windows

- Washing of the cans in the first washing/rinsing cabin

- Rinsing of the cans in the following rinsing cabins

- All cabins equipped with a patented spraying system with low water consumption

- Electrically heated tank for the first washing/rinsing cabin equipped with pumps, level control and temperature regulation

- Dripping area after washing, vertically arranged pins and drying blades

- Automatic level control of the tanks, equipped with safety unit against water shortage, temperature monitoring unit

- Stainless steel tank for collecting the dripping water below the washing machine

- Drying of the cans in the gas heated oven, low-energy design

- Chain guides made of PTFE (Teflon)

- Additional blowing nozzles for drying the interior and the rim of the cans

- Reliable system for sucking off the oven exhaust air

Leak detector

A photocell is used to detect if rays of light fall into the can through micro-holes. Defective cans are automatically ejected at the outfeed conveyor after the Leak detector. A 100% quality-control ensures that only complete secure cans leave the line.

The Leak detector can be placed on the outfeed conveyor of the Necking machine. Alternatively it can be integrated as a stand-alone machine in the line.

Necking machine

The cylinder is necked and shaped by necking dies up to the final can design. Processes as threading, curling, beading, registered embossing and debossing to create unique shapes and designs fitting the needs of your customers.

Any combination to create a 56 or 80 or 84 station necker system for advanced/modified alloys or DWI are possible.

Technical data

| Type | C200.28 | C200.28.VE | C200.36XVE | C200.40VE |

|---|---|---|---|---|

| Can diameter (mm) | 35-66 | 35-66 | 35-80 | 35-66 |

| Finished product length (mm after necking) | 110 – 250 | 110 – 250 | 110-275 | 105 – 250 |

| Number of stations | 28 | 28 | 36 | 40 |

| Total stroke (mm) | 150 | 132/216/280 | 110 - 270 | 110 - 270 |

| Usable stroke (mm) | 90 | 90/143/180 | 80 - 187 | 80 - 187 |

Special features

- Pneumatic holding grippers with electronic control for can detection guarantee a constant stable position of the can

- Tool quick-change system for maximum product flexibility

- Compressed air-assisted necking to enable even complicated shapes

- Bottom forming unit included in the standard supply

- Maximum accessibility to the machine working area for easy handling and setting of the tools

- Optimized can transfer systems between conveyors and drums

- Infinitely adjustable stroke (C200.36XVE and C200./C250.40VE)

- Electronic presetting device to set lubrication cycle frequency

- Possible application of all our proprietary tools allowing wide machining possibilities

- Frequency-controlled motors for rotating tools (C200.36XVE and C200./C250.40VE)

Accumulator 3

for accumulating the cans and compensating the asynchronous operation of decoration unit and necking machine.

Special features

- Two-part welded frame, mounted onto the floor with a capacity of 2000 cans

- Constant chain tension system

- Safety covering of the accumulator up to a height of 2,5 m with acrylic glass panes at the front side, rear and top with sheet metal covering. A complete covering of the accumulator is optionally available

Overvarnish lacquering machine

The overvarnish is applied to protect the decoration. According to the request of your customers also special effects like matt, semi matt, gloss or haptic can be provided.

Special features

- Can transfer from the conveyor chain to a mechanical take-off drum with size-independent vacuum pockets

- Mechanical indexing gear unit with 12 stations

- Mandrel quick change unit and monitoring of the correct clamping

- Infinitely variable mandrel drive by means of controlled servomotor

- Vacuum-assisted loading and steadying of the cans on the mandrels, before and during processing

- Three roller base-coating unit designed as V-type-coating unit

- Transfer unit with take-off control and two suction units for transporting the cans from the mandrels onto the chain pins

- Oven chamber with integrated chain guide

- Sprocket bearings with re-lubricating facility, installed outside the oven in an aluminium casing sealed towards the rear wall of the oven

- Possibility of can sampling for test purposes from the pins of the dryer chain, after drying of the clear varnish.

Printing machine

The printing unit, which can apply up to 9 colours, ensures the widest possible decoration variety for monoblock cans

Special features

- Can transfer from the conveyor chain to a mechanical take-off drum with size-independent vacuum pockets

- Mechanical indexing gear unit with 12 stations

- Mandrel quick change unit and monitoring of the correct clamping

- Infinitely variable mandrel drive by means of controlled servomotor

- Vacuum-assisted loading and steadying of the cans on the mandrels, before and during processing

- Printing unit with up to 9 colours

- Transfer unit with take-off control and two suction units for transporting the cans from the mandrels onto the chain pins

- Oven chamber with integrated chain guide

- Sprocket bearings with re-lubricating facility, installed outside the oven in an aluminium casing sealed towards the rear wall of the oven

- Possibility of can sampling for test purposes from the pins of the dryer chain, after drying of the printing inks.

Basecoat lacquering machine

The cylinder receives the base coat which is important for the stain resistance and excellent print quality. The base coat is dried in the first oven chamber of the decoration drying oven.

Special features

- Can transfer from the conveyor chain to a mechanical take-off drum with size-independent vacuum pockets

- Mechanical indexing gear unit with 12 stations

- Mandrel quick change unit and monitoring of the correct clamping

- Infinitely variable mandrel drive by means of controlled servomotor

- Vacuum-assisted loading and steadying of the cans on the mandrels, before and during processing

- Three roller base-coating unit designed as V-type-coating unit

- Transfer unit with take-off control and two suction units for transporting the cans from the mandrels onto the chain pins

- Oven chamber with integrated chain guide

- Sprocket bearings with re-lubricating facility, installed outside the oven in an aluminium casing sealed towards the rear wall of the oven

- Possibility of can sampling for test purposes from the pins of the dryer chain, after drying of the basecoat

Accumulator 2

for accumulating the cans and compensating the asynchronous operation of internal coating machine and decoration unit.

Special features

- Four-part welded frame, mounted onto the floor with a capacity of 3250 cans

- Constant chain tension system

- Safety covering of the accumulator up to a height of 2,5 m with acrylic glass panes at the front side, rear and top with sheet metal covering. A complete covering of the accumulator is optionally available

Internal coat dryer

for polymerizing the internal lacquer coat, electrically heated or alternatively by gas.

Special features

- 1,2 or 3 row transport chain with baskets

- Reduced wear-out of the transport chain and the chain wheels by cardan-based drive system

- Chain tension with weight, electronically monitored

- Easy accessibility to the dryer interior due to large doors

- Quadruple door look

- Isolated doors with special door hinges for synchronized door closing

- Large outer doors with smooth surface on the oven’s front and rear sides

- Quick and easy removal and reassembly of the shafts and chain wheels in case of service

Internal coating machine

A functional lacquer is applied to seal the inside of the cylinder using moveable spray lances. In the following oven with its cooling zone the inside lacquer is cured and hardened.

Special features

- Low vibration due to solid mechanical design

- Individual vacuum circuit for machine infeed and outfeed

- Increased user comfort by direct electro-pneumatic control of the spray guns by HMI

- Shorter cleaning times by optimized exhaust performance

- Height adjustable and horizontally moveable control panel

- Combinations with different internal coating drier options (1,2 or 3 rows)

Accumulator 1

for accumulating the cans and compensating the asynchronous operation of the washing machine and internal coating machine.

Special features

- Three-part welded frame, mounted onto the floor with a capacity of 2000 cans

- Constant chain tension system

- Connecting traverse at accumulator outfeed to bridge a walkway

- Safety covering of the accumulator up to a height of 2,5 m with acrylic glass panes at the front side, rear and top with sheet metal covering. A complete covering of the accumulator is optionally available

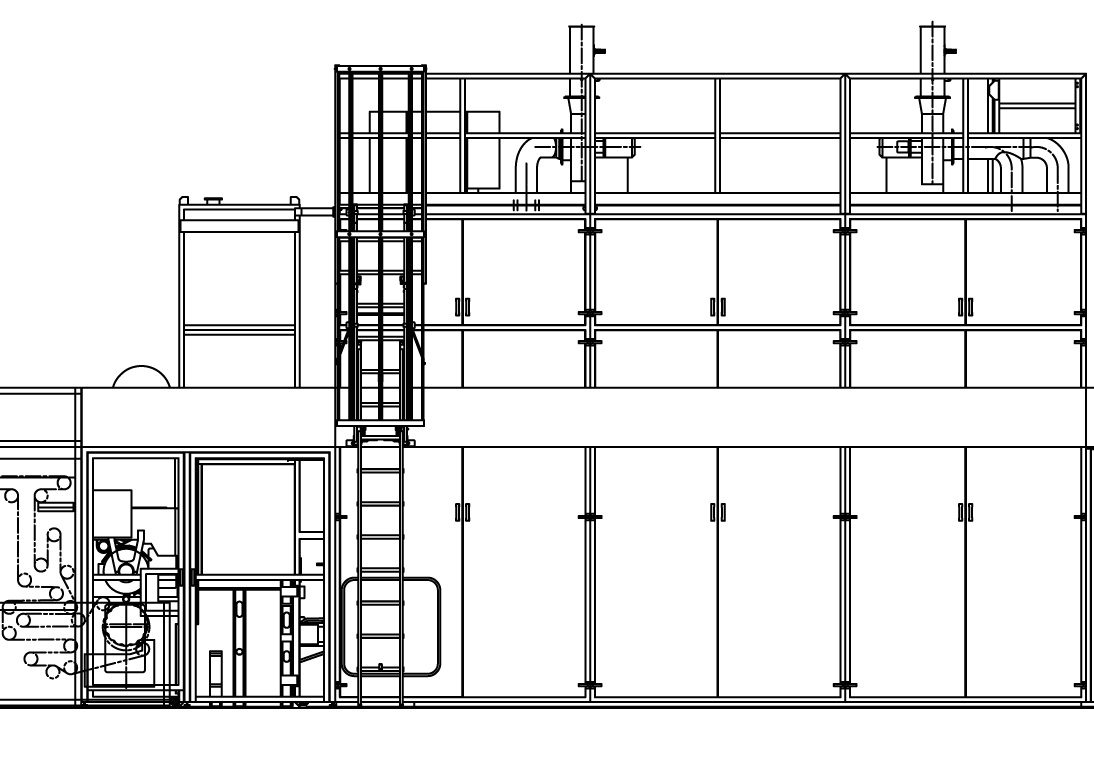

Washing machine

After pressing and trimming it is necessary to wash the lubricants from the cylinders. With our space-saving washing machines, designed in stainless steel, we offer an economic and energy-saving technology for a perfect washing result. Different machine types and a lot of special features allow as much customization as possible.

Technical data

| Type | CWM 45-5+ | CWM 55-5+ | CWM 66-5+ |

|---|---|---|---|

| Diameter range (mm) | 20-45 | 35-55 | 45-66 |

| Chain pitch | 3 x ¾” | 4 x ¾” | 5 x ¾” |

| Number of washing / rinsing cabins | 5 | 5 | 5 |

Special features

- Compact, space-saving stainless steel design, washing and rinsing cabins equipped with windows

- Reliable, adaptable infeed and outfeed system ensuring easy connection to the upstream and downstream machines

- Safe and reliable infeed and outfeed transfer through vacuum drums

- Gas or electrically heated stainless-steel drying oven with long dwell time and minimum energy consumption

- Newly designed jet spray system

- Detergent dosing by means of conductivity metering and dosing pump

- Dripping area between wet and dry zone, vertically arranged pins

- Electrically heated tanks for the degreasing cabins equipped with pumps, level control and temperature control

- Automatic level control of the tanks, equipped with a safety unit against water shortage and temperature monitoring unit

- Stainless steel tanks for collecting the dripping water below the machine

- Reliable system for sucking off the oven exhaust air

- New extra platform on top of the washing cabins for a better accessibility of the dryer

Trimming machine

The high-performance trimming machines, designed for trimming aluminium preforms to length and for brushing the body, have been fully equipped to allow flawless integration into automatic production lines. When designing the machine, particular importance was attached to ease of operation, quick tool change, easy access, solid process technology, high operational safety and little maintenance.

Technical data

| Type | MHB | MHB-G | SBB | SBM (without brushing) |

|---|---|---|---|---|

| Can diameter (mm) | 35-66 | 35-80 | 22-66 | 22-66 |

| Max. extruded overall length (mm) | 275 | 295 | 285 | 285 |

| Max. trimmed can length(mm) | 260 | 280 | 270 | 270 |

| Assumed wall thickness of cans (mm) | 0,2 - 0,6 | 0,2 - 1,0 | 0,35 - 0,8 | 0,35 - 0,8 |

Special features:

- Fully accessible from the front (MHB series), perfect control of all movements, easy change of the brush

- Centralized lubricating system

- The trimming system produces burrless cuts and guarantees a long tool life, precision adjustment in both axial and radial direction

- Mandrel quick-change systems

- Can scrap will be shredded into small pieces for easy suckoff

- Equipment for the separation and safe discharge of the trimming scrap

- Size parts are immediately located in the correct position

- The drum-type transfer unit makes sure the cans are safely transferred to the downstream equipment

- Continuously operating conveyor chain at the transfer station (MHB series)

- Deactivation of the oscillating movement of the grinding wheels possible (MHB)

- Automatic and smooth brush cleaning unit with adjustable cleaning cycle and use of commercial grinding wheels (MHB)

- Newly designed compact brushing unit for improved ergonomics, easier changeovers and maintenance (MHB)

Ironing machine

The cylinder wall thickness is optimized and the bottom is formed. This leads to constant geometrical features and light weight cans.

Special features

- Transfer of the cans from the outfeed conveyor of the impact extrusion press to the tray-type conveyor of the ironing press

- Punches with two punch holders

- Ironing rings and stripper exchangeable from above

- Pneumatically operated bottom forming unit with two dies, swing-off type

- Quick lock for facilitating punch and die exchange

- Electrical punch heating for temperature control of the punches

- Transfer of the cans to the synchronous transfer of the trimming machine

Press

If flexibility is required when producing a monoblock aluminium container, an Impact Extrusion Press is the first choice. A high performance toggle lever system produces aluminium cans with one stroke out of a slug. As a market leader, our presses are used all over the world for the production of monoblock aerosol cans.

Technical data

| Type | CP35 | CP55 | CP65 | CP75 | CP85 | Express 6000 |

|---|---|---|---|---|---|---|

| Can diameter (mm) | 10-30 | 19-45 | 25-45 | 25-53 | 35-66 | 43-80 |

| Max. extruded can length (mm) | 130 | 170 | 200 | 225 | 275 | 310 |

| Approx. wall thickness (mm) | 0,3 | 0,3 | 0,4 | 0,5 | 0,5 | 1,0 |

| Nominal press force (kN) | 800 | 1.400 | 1.600 | 2.500 | 4.000 | 6.000 |

Special features

- Sturdy frame, separate from the drive housing, for absorbing the extrusion loads; both parts made of spheroidal graphite iron

- Compact drive of the crankshaft via pneumatically controlled clutch-brake unit with spring loaded disc brake to allow controlled or immediate stops

- Speed-variable drive, creeping speed and facility for switching to reverse motion to facilitate the setting of the tooling

- Electromotive punch adjustment for correcting the bottom thickness during production

- Swing-off type slug feed and stripper frame of the take-off unit, resulting in short set-up times and simple size-part changes, optimized for high speed production

- Automatic permanent circulatory lubrication system with filter and offline filter system

- Take-off unit operating in absolute synchronism with the outfeed conveyor, ensuring trouble-free transfer of the products even in case of short extrusions and maximum stroke rates

- Inclined slug conveyor for direct feed of flat and domed slugs to the die

- Continuous rotary slug infeed system

Slug infeed

In the sorting and feeding unit the slugs are separated, aligned and fed into the extrusion press.

The processing of flat or domed slugs is possible.

Special features

- Storage container with inner lining to avoid damaged slugs

- Level control of the container by means of ultrasonic sensor

- Plate type conveyor belt

- Possibility to regulate the speed of the conveyor belt for different slug sizes

- Feed chute to the clamping-type elevator

- Clamping-type slug elevator, with overload protection at the transfer of the feed chute

Slug lubrication

The aluminium slugs are lubricated and transported to the sorting and feeding unit.

Special features

- Storage bin for storing slugs for one lubricating process

- Feeding of slugs to the lubricating barrel by means of conveyor belt

- Abrasion-proof lining of the barrel body with cover

- Manually assisted cover lifting device, monitored by limit switches

- Elevator-type conveyor belt for transporting the slugs

CMX

The new CMX Impact Extrusion line of mall//herlan with a production speed of 250 cpm exceeds limits. The machine technology to produce shaped aerosol cans at this speed in unrivalled worldwide. The increase of speed has been made possible for example by new transfer units and the optimisation of infeed drums in the front-end and decoration area. Even the production of shaped cans is possible at a speed of 250 cpm with our 40 station or even bigger necking system.

Packing machine

for strapping aluminium aerosol cans in bundles or layer blocks for pallet packing

Special features

- Ideal for aerosol cans

- Optimal grouping of cans

- Fast and gentle strapping via servo-controlled process

- Synchronous can transport from the upstream machine

- High production reliability and security

- Supplement machine to palletize the bundles are available

Postwasher

Our customized postwashing machines are equipped with a patented spraying system to ensure low water consumption.

A bypass function for the transport without washing/rinsing is included as standard.

Technical data

| Type | PWMx 45 | PWMx 55 | PWMx 66 |

|---|---|---|---|

| Max. Diameter (mm) | 45 | 55 | 66 |

| Chain pitch | 3 x ¾” | 4 x ¾” | 5 x ¾” |

| Number of washing / rinsing cabins | 2 | 2 | 2 |

Special features

- Stainless steel design, cabins equipped with windows

- Washing of the cans in the first washing/rinsing cabin

- Rinsing of the cans in the following rinsing cabins

- All cabins equipped with a patented spraying system with low water consumption

- Electrically heated tank for the first washing/rinsing cabin equipped with pumps, level control and temperature regulation

- Dripping area after washing, vertically arranged pins and drying blades

- Automatic level control of the tanks, equipped with safety unit against water shortage, temperature monitoring unit

- Stainless steel tank for collecting the dripping water below the washing machine

- Drying of the cans in the gas heated oven, low-energy design

- Chain guides made of PTFE (Teflon)

- Additional blowing nozzles for drying the interior and the rim of the cans

- Reliable system for sucking off the oven exhaust air

Leak detector

A photocell is used to detect if rays of light fall into the can through micro-holes. Defective cans are automatically ejected at the outfeed conveyor after the Leak detector. A 100% quality-control ensures that only complete secure cans leave the line.

The Leak detector can be placed on the outfeed conveyor of the Necking machine. Alternatively it can be integrated as a stand-alone machine in the line.

Necking machine

The cylinder is necked and shaped by necking dies up to the final can design. Processes as threading, curling, beading, registered embossing and debossing to create unique shapes and designs fitting the needs of your customers.

Technical data

| Type | C250.40VE |

|---|---|

| Can diameter (mm) | 35 - 66 |

| Finished product length (mm after necking) | 105 - 250 |

| Number of stations | 40 |

| Total stroke (mm) | 110 - 270 |

| Usable stroke (mm) | 86 - 202 |

Special features

- Pneumatic holding grippers with electronic control for can detection guarantee a constant stable position of the can

- Tool quick-change system for maximum product flexibility

- Compressed air-assisted necking to enable even complicated shapes

- Bottom forming unit included in the standard supply

- Maximum accessibility to the machine working area for easy handling and setting of the tools

- Optimized can transfer systems between conveyors and drums

- Infinitely adjustable stroke

- Electronic presetting device to set lubrication cycle frequency

- Possible application of all our proprietary tools allowing wide machining possibilities

- Frequency-controlled motors for rotating tools

Accumulator 3

for accumulating the cans and compensating the asynchronous operation of decoration unit and necking machine.

Special features

- Two-part welded frame, mounted onto the floor

- Constant chain tension system

- Safety covering of the accumulator up to a height of 2,5 m with acrylic glass panes at the front side, rear and top with sheet metal covering. A complete covering of the accumulator is optionally available

Overvarnish lacquering machine

The overvarnish is applied to protect the decoration. According to the request of your customers also special effects like matt, semi matt, gloss or haptic can be provided.

Special features

- Can transfer from the conveyor chain to a mechanical take-off drum with size-independent vacuum pockets

- Mechanical indexing gear unit with 12 stations

- Mandrel quick change unit and monitoring of the correct clamping

- Infinitely variable mandrel drive by means of controlled servomotor

- Vacuum-assisted loading and steadying of the cans on the mandrels, before and during processing

- Three roller base-coating unit designed as V-type-coating unit

- Transfer unit with take-off control and two suction units for transporting the cans from the mandrels onto the chain pins

- Oven chamber with integrated chain guide

- Sprocket bearings with re-lubricating facility, installed outside the oven in an aluminium casing sealed towards the rear wall of the oven

- Possibility of can sampling for test purposes from the pins of the dryer chain, after drying of the clear varnish.

Printing machine

The printing unit, which can apply up to 9 colours, ensures the widest possible decoration variety for monoblock cans

Special features

- Can transfer from the conveyor chain to a mechanical take-off drum with size-independent vacuum pockets

- Mechanical indexing gear unit with 12 stations

- Mandrel quick change unit and monitoring of the correct clamping

- Infinitely variable mandrel drive by means of controlled servomotor

- Vacuum-assisted loading and steadying of the cans on the mandrels, before and during processing

- Printing unit with up to 9 colours

- Transfer unit with take-off control and two suction units for transporting the cans from the mandrels onto the chain pins

- Oven chamber with integrated chain guide

- Sprocket bearings with re-lubricating facility, installed outside the oven in an aluminium casing sealed towards the rear wall of the oven

- Possibility of can sampling for test purposes from the pins of the dryer chain, after drying of the printing inks.

Basecoat lacquering machine

The cylinder receives the base coat which is important for the stain resistance and excellent print quality. The base coat is dried in the first oven chamber of the decoration drying oven.

Special features

- Can transfer from the conveyor chain to a mechanical take-off drum with size-independent vacuum pockets

- Mechanical indexing gear unit with 12 stations

- Mandrel quick change unit and monitoring of the correct clamping

- Infinitely variable mandrel drive by means of controlled servomotor

- Vacuum-assisted loading and steadying of the cans on the mandrels, before and during processing

- Three roller base-coating unit designed as V-type-coating unit

- Transfer unit with take-off control and two suction units for transporting the cans from the mandrels onto the chain pins

- Oven chamber with integrated chain guide

- Sprocket bearings with re-lubricating facility, installed outside the oven in an aluminium casing sealed towards the rear wall of the oven

- Possibility of can sampling for test purposes from the pins of the dryer chain, after drying of the basecoat

Accumulator 2

for accumulating the cans and compensating the asynchronous operation of internal coating machine and decoration unit.

Special features

- Four-part welded frame, mounted onto the floor

- Constant chain tension system

- Safety covering of the accumulator up to a height of 2,5 m with acrylic glass panes at the front side, rear and top with sheet metal covering. A complete covering of the accumulator is optionally available

Internal coat dryer

for polymerizing the internal lacquer coat, electrically heated or alternatively by gas.

Special features

- 1,2 or 3 row transport chain with baskets

- Reduced wear-out of the transport chain and the chain wheels by cardan-based drive system

- Chain tension with weight, electronically monitored

- Easy accessibility to the dryer interior due to large doors

- Quadruple door look

- Isolated doors with special door hinges for synchronized door closing

- Large outer doors with smooth surface on the oven’s front and rear sides

- Quick and easy removal and reassembly of the shafts and chain wheels in case of service

Internal coating machine

A functional lacquer is applied to seal the inside of the cylinder using moveable spray lances. In the following oven with its cooling zone the inside lacquer is cured and hardened.

Special features

- Low vibration due to solid mechanical design

- Individual vacuum circuit for machine infeed and outfeed

- Increased user comfort by direct electro-pneumatic control of the spray guns by HMI

- Shorter cleaning times by optimized exhaust performance

- Height adjustable and horizontally moveable control panel

- Combinations with different internal coating drier options (1,2 or 3 rows)

Accumulator 1

for accumulating the cans and compensating the asynchronous operation of the washing machine and internal coating machine.

Special features

- Three-part welded frame, mounted onto the floor

- Constant chain tension system

- Connecting traverse at accumulator outfeed to bridge a walkway

- Safety covering of the accumulator up to a height of 2,5 m with acrylic glass panes at the front side, rear and top with sheet metal covering. A complete covering of the accumulator is optionally available

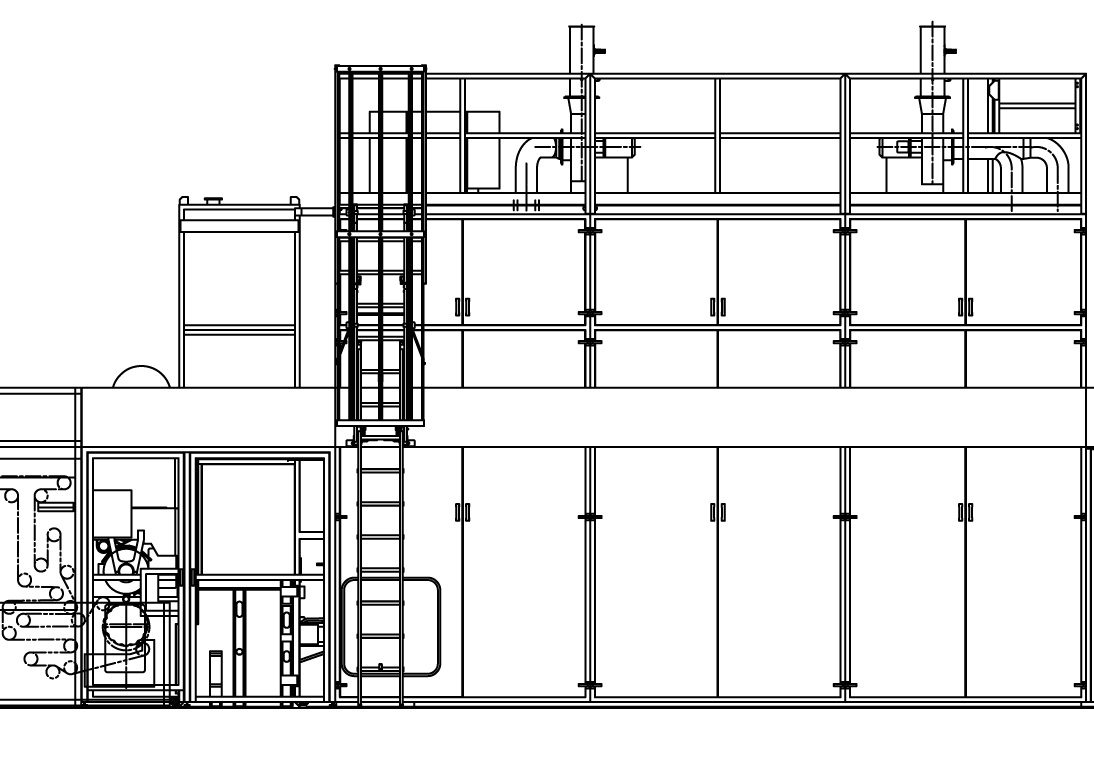

Washing machine

After pressing and trimming it is necessary to wash the lubricants from the cylinders. With our space-saving washing machines, designed in stainless steel, we offer an economic and energy-saving technology for a perfect washing result. A lot of special features allow as much customization as possible.

Technical data

| Type | CWMx 59-5+ | CWMx 66-8 |

|---|---|---|

| Diameter range (mm) | 35-59 | 45-66 |

| Chain pitch | 4 x ¾” | 5 x ¾” |

| Number of washing / rinsing cabins | 5 | 8 |

Special features

- Compact, space-saving stainless steel design, washing and rinsing cabins equipped with windows

- Reliable, adaptable infeed and outfeed system ensuring easy connection to the upstream and downstream machines

- Safe and reliable infeed and outfeed transfer through vacuum drums

- Gas or electrically heated stainless-steel drying oven with long dwell time and minimum energy consumption

- Newly designed jet spray system

- Detergent dosing by means of conductivity metering and dosing pump

- Dripping area between wet and dry zone, vertically arranged pins

- Electrically heated tanks for the degreasing cabins equipped with pumps, level control and temperature control

- Automatic level control of the tanks, equipped with a safety unit against water shortage and temperature monitoring unit

- Stainless steel tanks for collecting the dripping water below the machine

- Reliable system for sucking off the oven exhaust air

- New extra platform on top of the washing cabins for a better accessibility of the dryer

Trimming machine

The high-performance trimming machines, designed for trimming aluminium preforms to length and for brushing the body, have been fully equipped to allow flawless integration into automatic production lines. When designing the machine, particular importance was attached to ease of operation, quick tool change, easy access, solid process technology, high operational safety and little maintenance.

Technical data

| Type | MHBx |

|---|---|

| Can diameter (mm) | 35 - 66 |

| Max. extruded overall length (mm) | 275 |

| Max. trimmed can length(mm) | 260 |

| Assumed wall thickness of cans (mm) | 0,2 - 0,6 |

Special features:

- Fully accessible from the front, perfect control of all movements, easy change of the brush

- Centralized lubricating system

- The trimming system produces burr less cuts and guarantees a long tool life, precision adjustment in both axial and radial direction

- Mandrel quick-change systems

- Can scrap will be shredded into small pieces for easy suckoff

- Equipment for the separation and safe discharge of the trimming scrap

- Size parts are immediately located in the correct position

- The drum-type transfer unit makes sure the cans are safely transferred to the downstream equipment

- Continuously operating conveyor chain at the transfer station

- Deactivation of the oscillating movement of the grinding wheels possible

- Automatic and smooth brush cleaning unit with adjustable cleaning cycle and use of commercial grinding wheels

- Newly designed compact brushing unit for improved ergonomics, easier changeovers and maintenance

Ironing machine

The cylinder wall thickness is optimized and the bottom is formed. This leads to constant geometrical features and light weight cans.

Special features

- Transfer of the cans from the outfeed conveyor of the impact extrusion - press to the tray-type conveyor of the ironing press

- Punches with two punch holders

- Ironing rings and stripper exchangeable from above

- Pneumatically operated bottom forming unit with two dies, swing-off type

- Quick lock for facilitating punch and die exchange

- Electrical punch heating for temperature control of the punches

- Transfer of the cans to the synchronous transfer of the trimming machine

Press

If flexibility is required when producing a monoblock aluminium container, an Impact Extrusion Press is the first choice. A high performance toggle lever system produces aluminium cans with one stroke out of a slug. As a market leader, our presses are used all over the world for the production of monoblock aerosol cans.

Technical data

| Type | Express 4000 |

|---|---|

| Can diameter (mm) | 35-66 |

| Max. extruded can length (mm) | 275 |

| Approx. wall thickness (mm) | 0,5 |

| Nominal press force (kN) | 4.000 |

Special features

- Sturdy frame, separate from the drive housing, for absorbing the extrusion loads; both parts made of spheroidal graphite iron

- Compact drive of the crankshaft via pneumatically controlled clutch-brake unit with spring loaded disc brake to allow controlled or immediate stops

- Speed-variable drive, creeping speed and facility for switching to reverse motion to facilitate the setting of the tooling

- Electromotive punch adjustment for correcting the bottom thickness during production

- Swing-off type slug feed and stripper frame of the take-off unit, resulting in short set-up times and simple size-part changes, optimized for high speed production

- Automatic permanent circulatory lubrication system with filter and offline filter system

- Take-off unit operating in absolute synchronism with the outfeed conveyor, ensuring trouble-free transfer of the products even in case of short extrusions and maximum stroke rates

- Inclined slug conveyor for direct feed of flat and domed slugs to the die

- Continuous rotary slug infeed system

Slug infeed

In the sorting and feeding unit the slugs are separated, aligned and fed into the extrusion press. The processing of flat or domed slugs is possible.

Special features

- Storage container with inner lining to avoid damaged slugs

- Level control of the container by means of ultrasonic sensor

- Plate type conveyor belt

- Possibility to regulate the speed of the conveyor belt for different slug sizes

- Feed chute to the clamping-type elevator

- Clamping-type slug elevator, with overload protection at the transfer of the feed chute

Slug lubrication

The aluminium slugs are lubricated and transported to the sorting and feeding unit.

Special features

- Storage bin for storing slugs for one lubricating process

- Feeding of slugs to the lubricating barrel by means of conveyor belt

- Abrasion-proof lining of the barrel body with cover

- Manually assisted cover lifting device, monitored by limit switches

- Elevator-type conveyor belt for transporting the slugs

CMC180G

This line is your choice for cans with a bigger diameter and/or greater can length.

Packing machine

for strapping aluminium aerosol cans in bundles or layer blocks for pallet packing

Special features

- Ideal for aerosol cans

- Optimal grouping of cans

- Fast and gentle strapping via servo-controlled process

- Synchronous can transport from the upstream machine

- High production reliability and security

- Supplement machine to palletize the bundles are available

Postwasher

Our customized postwashing machines are equipped with a patented spraying system to ensure low water consumption.

A bypass function for the transport without washing/rinsing is included as standard.

Technical data

| Type | PWM 80 |

|---|---|

| Max. Diameter (mm) | 80 |

| Chain pitch | 6 x ¾” |

| Number of washing / rinsing cabins | 2 |

Special features

- Stainless steel design, cabins equipped with windows

- Washing of the cans in the first washing/rinsing cabin

- Rinsing of the cans in the following rinsing cabins

- All cabins equipped with a patented spraying system with low water consumption

- Electrically heated tank for the first washing/rinsing cabin equipped with pumps, level control and temperature regulation

- Dripping area after washing, vertically arranged pins and drying blades

- Automatic level control of the tanks, equipped with safety unit against water shortage, temperature monitoring unit

- Stainless steel tank for collecting the dripping water below the washing machine

- Drying of the cans in the gas heated oven, low-energy design

- Chain guides made of PTFE (Teflon)

- Additional blowing nozzles for drying the interior and the rim of the cans

- Reliable system for sucking off the oven exhaust air

Leak detector

A photocell is used to detect if rays of light fall into the can through micro-holes. Defective cans are automatically ejected at the outfeed conveyor after the Leak detector. A 100% quality-control ensures that only complete secure cans leave the line.

The Leak detector can be placed on the outfeed conveyor of the Necking machine. Alternatively it can be integrated as a stand-alone machine in the line.

Necking machine

The cylinder is necked and shaped by necking dies up to the final can or bottle design. Processes as threading, curling, beading, registered embossing and debossing to create unique shapes and designs fitting the needs of your customers.

Technical data

| Type | C200.36XVE |

|---|---|

| Can diameter (mm) | 35-80 |

| Finished product length (mm after necking) | 110-275 |

| Number of stations | 36 |

| Total stroke (mm) | 110 - 270 |

| Usable stroke (mm) | 80 - 187 |

Special features

- Pneumatic holding grippers with electronic control for can detection guarantee a constant stable position of the can

- Tool quick-change system for maximum product flexibility

- Compressed air-assisted necking to enable even complicated shapes

- Bottom forming unit included in the standard supply

- Maximum accessibility to the machine working area for easy handling and setting of the tools

- Optimized can transfer systems between conveyors and drums

- Infinitely adjustable stroke

- Electronic presetting device to set lubrication cycle frequency

- Possible application of all our proprietary tools allowing wide machining possibilities

- Frequency-controlled motors for rotating tools

Accumulator 3

for accumulating the cans and compensating the asynchronous operation of decoration unit and necking machine.

Special features

- Two-part welded frame, mounted onto the floor with a capacity of 2100 cans

- Constant chain tension system

- Safety covering of the accumulator up to a height of 2,5 m with acrylic glass panes at the front side, rear and top with sheet metal covering. A complete covering of the accumulator is optionally available

Overvarnish lacquering machine

The overvarnish is applied to protect the decoration. According to the request of your customers also special effects like matt, semi matt, gloss or haptic can be provided.

Special features

- Can transfer from the conveyor chain to a mechanical take-off drum with size-independent vacuum pockets

- Mechanical indexing gear unit with 12 stations

- Mandrel quick change unit and monitoring of the correct clamping

- Infinitely variable mandrel drive by means of controlled servomotor

- Unit for checking whether the cans have been correctly loaded on the mandrels

- Vacuum-assisted loading and steadying of the cans on the mandrels, before and during processing

- Three roller base-coating unit designed as V-type-coating unit

- Transfer unit with take-off control and two suction units for transporting the cans from the mandrels onto the chain pins

- Oven chamber with integrated chain guide

- Sprocket bearings with re-lubricating facility, installed outside the oven in an aluminium casing sealed towards the rear wall of the oven

- Possibility of can sampling for test purposes from the pins of the dryer chain, after drying of the clear varnish.

Printing machine

The printing unit, which can apply up to 9 colours, ensures the widest possible decoration variety for monoblock cans

Special features

- Can transfer from the conveyor chain to a mechanical take-off drum with size-independent vacuum pockets

- Mechanical indexing gear unit with 12 stations

- Mandrel quick change unit and monitoring of the correct clamping

- Infinitely variable mandrel drive by means of controlled servomotor

- Unit for checking whether the cans have been correctly loaded on the mandrels

- Printing unit with up to 9 colours

- Transfer unit with take-off control and two suction units for transporting the cans from the mandrels onto the chain pins

- Oven chamber with integrated chain guide

- Sprocket bearings with re-lubricating facility, installed outside the oven in an aluminium casing sealed towards the rear wall of the oven

- Possibility of can sampling for test purposes from the pins of the dryer chain, after drying of the printing inks.

Basecoat lacquering

The cylinder receives the base coat which is important for the stain resistance and excellent print quality. The base coat is dried in the first oven chamber of the decoration drying oven.

Special features

- Can transfer from the conveyor chain to a mechanical take-off drum with size-independent vacuum pockets

- Mechanical indexing gear unit with 12 stations

- Mandrel quick change unit and monitoring of the correct clamping

- Infinitely variable mandrel drive by means of controlled servomotor

- Unit for checking whether the cans have been correctly loaded on the mandrels

- Vacuum-assisted loading and steadying of the cans on the mandrels, before and during processing

- Three roller base-coating unit designed as V-type-coating unit

- Transfer unit with take-off control and two suction units for transporting the cans from the mandrels onto the chain pins

- Oven chamber with integrated chain guide

- Sprocket bearings with re-lubricating facility, installed outside the oven in an aluminium casing with sealed towards the rear wall of the oven

- Possibility of can sampling for test purposes from the pins of the dryer chain, after drying of the basecoat

Accumulator 2

for accumulating the cans and compensating the asynchronous operation of internal coating machine and decoration unit.

Special features

- Four-part welded frame, mounted onto the floor with a capacity of 3300 cans

- Constant chain tension system

- Safety covering of the accumulator up to a height of 2,5 m with acrylic glass panes at the front side, rear and top with sheet metal covering. A complete covering of the accumulator is optionally available

Internal coat dryer

for polymerizing the internal lacquer coat, electrically heated or alternatively by gas.

Special features

- 1,2 or 3 row transport chain with baskets

- Reduced wear-out of the transport chain and the chain wheels by cardan-based drive system

- Chain tension with weight, electronically monitored

- Easy accessibility to the dryer interior due to large doors

- Quadruple door look

- Isolated doors with special door hinges for synchronized door closing

- Large outer doors with smooth surface on the oven’s front and rear sides

- Quick and easy removal and reassembly of the shafts and chain wheels in case of service

Internal coating machine

A functional lacquer is applied to seal the inside of the cylinder using moveable spray lances. In the following oven with its cooling zone the inside lacquer is cured and hardened.

Special features

- Low vibration due to solid mechanical design

- Individual vacuum circuit for machine infeed and outfeed

- Increased user comfort by direct electro-pneumatic control of the spray guns by HMI

- Shorter cleaning times by optimized exhaust performance

- Height adjustable and horizontally moveable control panel

- Combinations with different internal coating dryer options (1,2 or 3 rows)

Accumulator 1

for accumulating the cans and compensating the asynchronous operation of the washing machine and internal coating machine.

Special features

- Three-part welded frame, mounted onto the floor with a capacity of 2100 cans

- Constant chain tension system

- Connecting traverse at accumulator outfeed to bridge a walkway

- Safety covering of the accumulator up to a height of 2,5 m with acrylic glass panes at the front side, rear and top with sheet metal covering. A complete covering of the accumulator is optionally available

Washing machine

After pressing and trimming it is necessary to wash the lubricants from the cylinders. With our space-saving washing machines, designed in stainless steel, we offer an economic and energy-saving technology for a perfect washing result. A lot of special features allow as much customization as possible.

Technical data

| Type | CWM 80-5+ |

|---|---|

| Diameter range (mm) | 45-80 |

| Chain pitch | 6 x ¾” |

| Number of washing / rinsing cabins | 5 |

Special features

- Compact, space-saving stainless steel design, washing and rinsing cabins equipped with windows

- Reliable, adaptable infeed and outfeed system ensuring easy connection to the upstream and downstream machines

- Safe and reliable infeed and outfeed transfer through vacuum drums

- Gas or electrically heated stainless-steel drying oven with long dwell time and minimum energy consumption

- Newly designed jet spray system

- Detergent dosing by means of conductivity metering and dosing pump

- Dripping area between wet and dry zone, vertically arranged pins

- Electrically heated tanks for the degreasing cabins equipped with pumps, level control and temperature control

- Automatic level control of the tanks, equipped with a safety unit against water shortage and temperature monitoring unit

- Stainless steel tanks for collecting the dripping water below the machine

- Reliable system for sucking off the oven exhaust air

- New extra platform on top of the washing cabins for a better accessibility of the dryer

Trimming machine

The high-performance trimming machines, designed for trimming aluminium preforms to length and for brushing the body, have been fully equipped to allow flawless integration into automatic production lines. When designing the machine, particular importance was attached to ease of operation, quick tool change, easy access, solid process technology, high operational safety and little maintenance.

Technical data

| Type | MHB-G |

|---|---|

| Can diameter (mm) | 35 - 80 |

| Max. extruded overall length (mm) | 295 |

| Max. trimmed can length(mm) | 280 |

| Assumed wall thickness of cans (mm) | 0,2 - 1,0 |

Special features:

- Fully accessible from the front, perfect control of all movements, easy change of the brush

- Centralized lubricating system

- The trimming system produces burr less cuts and guarantees a long tool life, precision adjustment in both axial and radial direction

- Mandrel quick-change systems

- Can scrap will be shredded into small pieces for easy suckoff

- Equipment for the separation and safe discharge of the trimming scrap

- Size parts are immediately located in the correct position

- The drum-type transfer unit makes sure the cans are safely transferred to the downstream equipment

- Continuously operating conveyor chain at the transfer station

Press

If flexibility is required when producing a monoblock aluminium container, an Impact Extrusion Press is the first choice. A high performance toggle lever system produces aluminium cans with one stroke out of a slug. As a market leader, our presses are used all over the world for the production of monoblock aerosol cans.

Technical data

| Type | Express 6000 |

|---|---|

| Can diameter (mm) | 53-80 |

| Max. extruded can length (mm) | 310 |

| Approx. wall thickness (mm) | 1,0 |

| Nominal press force (kN) | 6.000 |

Special features

- Sturdy frame, separate from the drive housing, for absorbing the extrusion loads; both parts made of spheroidal graphite iron

- Compact drive of the crankshaft via pneumatically controlled clutch-brake unit with spring loaded disc brake to allow controlled or immediate stops

- Speed-variable drive, creeping speed and facility for switching to reverse motion to facilitate the setting of the tooling

- Electromotive punch adjustment for correcting the bottom thickness during production

- Swing-off type slug feed and stripper frame of the take-off unit, resulting in short set-up times and simple size-part changes, optimized for high speed production

- Automatic permanent circulatory lubrication system with filter and offline filter system

- Take-off unit operating in absolute synchronism with the outfeed conveyor, ensuring trouble-free transfer of the products even in case of short extrusions and maximum stroke rates

- Inclined slug conveyor for direct feed of flat and domed slugs to the die

- Continuous rotary slug infeed system

Slug infeed

In the sorting and feeding unit the slugs are separated, aligned and fed into the extrusion press.

The processing of flat or domed slugs is possible.

Special features

- Storage container with inner lining to avoid damaged slugs

- Level control of the container by means of ultrasonic sensor

- Plate type conveyor belt

- Possibility to regulate the speed of the conveyor belt for different slug sizes

- Feed chute to the clamping-type elevator

- Clamping-type slug elevator, with overload protection at the transfer of the feed chute

Slug lubrication

The aluminium slugs are lubricated and transported to the sorting and feeding unit.

Special features

- Storage bin for storing slugs for one lubricating process

- Feeding of slugs to the lubricating barrel by means of conveyor belt

- Abrasion-proof lining of the barrel body with cover

- Manually assisted cover lifting device, monitored by limit switches

- Elevator-type conveyor belt for transporting the slugs

Individual machines

All our machines are also available to be placed in an existing line. Our experts will take care of the integration into the line and the synchronisation with the preceding and succeeding machines.

DWI Production Lines:

In the DWI customized production line a cup is punched out of an aluminium sheet, fed by a coil. In the bodymaker the cup is ironed to a cylinder and the bottom is formed. Subsequently the cylinder is cut to length, decorated, necked and shaped to an Aluminium Aerosol Can.

Hi-Flex DWI200

If you deal with large lot sizes, less shapes per line and would like to save material, you should go for a DWI line. The mall//herlan DWI line is the perfect solution for a flexible and cost-effective production of aluminium cylinders out of coiled material.

Packing machine

All shapes and sizes of unfilled cans can be palletized on this machine

Special features

- Ideal for aerosol cans

- Optimal grouping of cans

- Simple and quick changeover of form sets

- Synchronous can transfer

- High production reliability and security

- Aerosol cans palletized in bundles or full-layer

Postwasher

Our customized postwashing machines are equipped with a patented spraying system to ensure low water consumption when washing off lubricants after necking.

A bypass function for the transport without washing/rinsing is included as standard.

Technical data

| Type | PWM 66 |

|---|---|

| Max. Diameter (mm) | 66 |

| Chain pitch | 5 x ¾” |

| Number of washing / rinsing cabins | 2 |

Special features

- Stainless steel design, cabins equipped with windows

- Washing of the cans in the first washing/rinsing cabins

- Rinsing of the cans in the following rinsing cabins

- All cabins equipped with a patented spraying system with low water consumption

- Electrically heated tank for the first washing/rinsing cabin equipped with pumps, level control and temperature regulation

- Dripping area after washing, vertically arranged pins and drying blades

- Automatic level control of the tanks, equipped with safety unit against water shortage, temperature monitoring unit

- Stainless steel tank for collecting the dripping water below the washing machine

- Drying of the cans in the gas heated oven, low-energy design

- Chain guides made of PTFE (Teflon)

- Additional blowing nozzles for drying the interior and the rim of the cans

- Reliable system for sucking off the oven exhaust air

LD

Leak detector

A photocell is used to detect if rays of light fall into the can through micro-holes. Defective cans are automatically ejected at the outfeed conveyor after the Leak detector. A 100% quality-control ensures that only complete secure cans leave the line.

The Leak detector can be placed on the outfeed conveyor of the Necking machine. Alternatively it can be integrated as a stand-alone machine in the line.

Necking machine

The cylinder is necked and shaped by necking dies up to the final can design. Processes as threading, curling, beading, registered em- and debossing to create unique shapes and designs fitting the needs of your customers.

Technical data

| Type | C200.80VE |

|---|---|

| Can Diameter (mm) | 35 - 66 |

| Finished product length (mm after necking) | 105 - 250 |

| Number of stations | 80 |

| Total stroke (mm) | 110 - 270 |

| Usable stroke (mm) | 80 - 187 |

Special features

- 2 tool carrier plates including can transfer

- Pneumatic holding grippers with electronic control for can detection guarantee a constant stable position of the can

- Tool quick-change system for maximum product flexibility

- Compressed air-assisted necking to enable even complicated shapes

- Bottom forming unit included in the standard supply

- Maximum accessibility to the machine working area for easy handling and setting of the tools

- Optimized can transfer systems between conveyors and drums

- Infinitely adjustable stroke

- Electronic presetting device to set lubrication cycle frequency

- Possible application of all our proprietary tools allowing wide machining possibilities

- Frequency-controlled motors for rotating tools

Accu 3

for accumulating the cans and compensating the asynchronous operation of decoration unit and necking machine.

Special features

- Two-part welded frame, mounted onto the floor

- Constant chain tension system

- Safety covering of the accumulator up to a height of 2,5 m with acrylic glass panes at the front side, rear and top with sheet metal covering. A complete covering of the accumulator is optionally available.

Overvarnish lacquering machine

The overvarnish is applied to protect the decoration. According to the request of your customers also special effects like matt, semi matt, gloss or haptic can be provided.

Special features

- Can transfer from the conveyor chain to a mechanical take-off drum with size-independent vacuum pockets

- Mechanical indexing gear unit with 12 stations

- Mandrel quick change unit and monitoring of the correct clamping

- Infinitely variable mandrel drive by means of controlled servomotor

- Vacuum-assisted loading and steadying of the cans on the mandrels, before and during processing

- Three roller base-coating unit designed as V-type-coating unit

- Transfer unit with take-off control and two suction units for transporting the cans from the mandrels onto the chain pins

- Oven chamber with integrated chain guide

- Sprocket bearings with re-lubricating facility, installed outside the oven in an aluminium casing sealed towards the rear wall of the oven

- Possibility of can sampling for test purposes from the pins of the dryer chain, after drying of the clear varnish.

Printing machine

The printing unit, which can apply up to 9 colours, ensures the widest possible decoration variety for monoblock packagings

Special features

- Can transfer from the conveyor chain to a mechanical take-off drum with size-independent vacuum pockets

- Mechanical indexing gear unit with 12 stations

- Mandrel quick change unit and monitoring of the correct clamping

- Infinitely variable mandrel drive by means of controlled servomotor

- Vacuum-assisted loading and steadying of the cans on the mandrels, before and during processing

- Printing unit with up to 9 colours

- Transfer unit with take-off control and two suction units for transporting the cans from the mandrels onto the chain pins

- Oven chamber with integrated chain guide

- Sprocket bearings with re-lubricating facility, installed outside the oven in an aluminium casing sealed towards the rear wall of the oven

- Possibility of can sampling for test purposes from the pins of the dryer chain, after drying of the printing inks.

Basecoat

Basecoat lacquering machine

The cylinder receives the base coat which is important for the stain resistance and excellent print quality. The base coat is dried in the first oven chamber of the decoration drying oven.

Special features

- Can transfer from the conveyor chain to a mechanical take-off drum with size-independent vacuum pockets

- Mechanical indexing gear unit with 12 stations

- Mandrel quick change unit and monitoring of the correct clamping

- Infinitely variable mandrel drive by means of controlled servomotor

- Vacuum-assisted loading and steadying of the cans on the mandrels, before and during processing

- Three roller base-coating unit designed as V-type-coating unit

- Transfer unit with take-off control and two suction units for transporting the cans from the mandrels onto the chain pins

- Oven chamber with integrated chain guide

- Sprocket bearings with re-lubricating facility, installed outside the oven in an aluminium casing sealed towards the rear wall of the oven

- Possibility of can sampling for test purposes from the pins of the dryer chain, after drying of the basecoat

Accumulator 2

for accumulating the cans and compensating the asynchronous operation of internal coating machine and decoration unit.

Special features

- Four-part welded frame, mounted onto the floor

- Constant chain tension system

- Safety covering of the accumulator up to a height of 2,5 m with acrylic glass panes at the front side, rear and top with sheet metal covering. A complete covering of the accumulator is optionally available.

Internal coat dryer

for polymerizing the internal lacquer coat, electrically heated or alternatively by gas.

Special features

- 1,2 or 3 row transport chain with baskets

- Reduced wear-out of the transport chain and the chain wheels by cardan-based driven system

- Chain tension with weight, electronically monitored

- Easy accessibility to the dryer interior due to large doors

- Quadruple door look

- Isolated doors with special door hinges for synchronized door closing

- Large outer doors with smooth surface on the oven’s front and rear sides

- Quick and easy removal and reassembly of the shafts and chain wheels in case of service

Internal coating

Internal coating machine

A functional lacquer is applied to seal the inside of the cylinder using moveable spray lances. In the following oven with its cooling zone the inside lacquer is cured and hardened.

Special features

- Low vibration due to solid mechanical design