Product lines

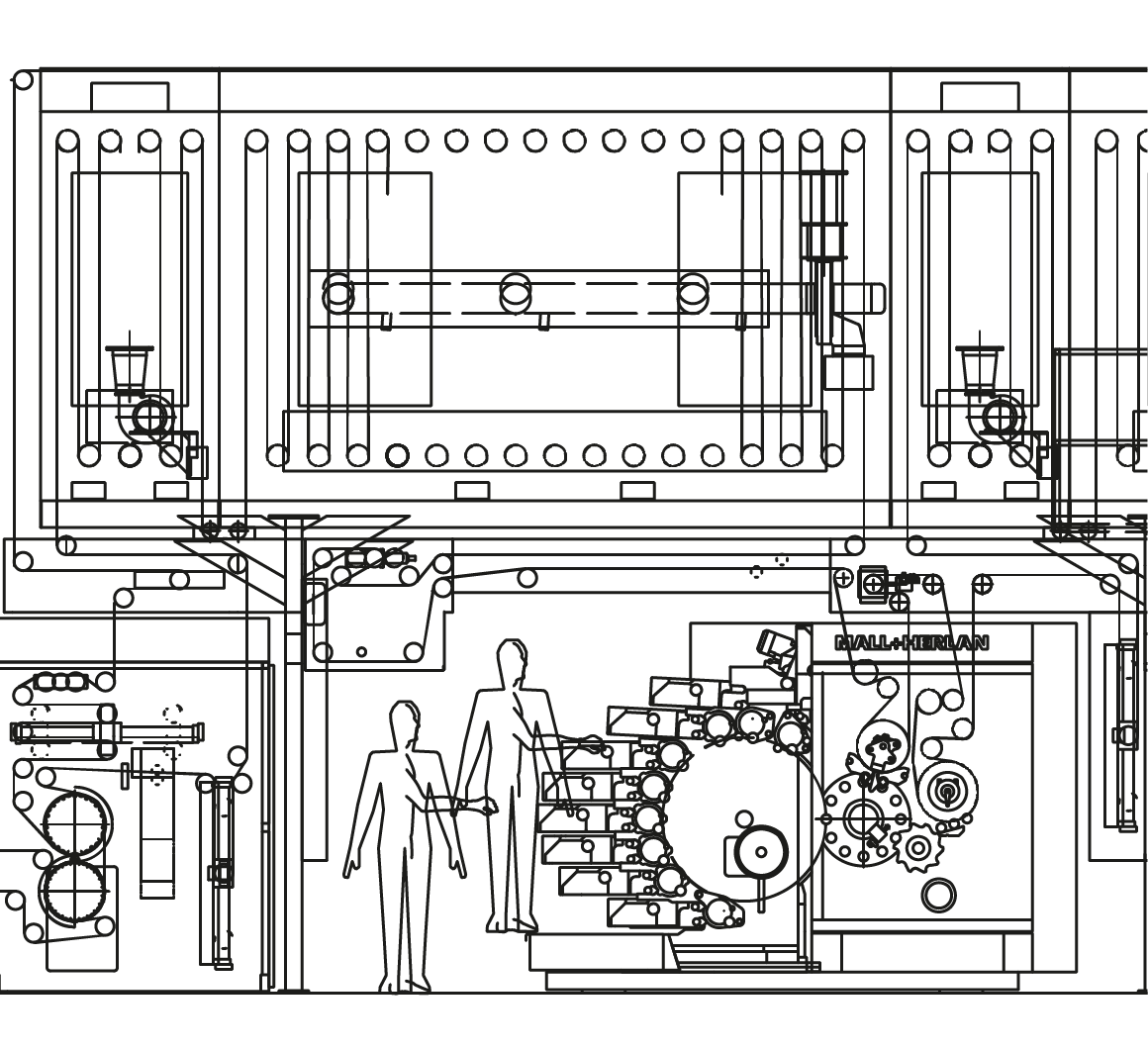

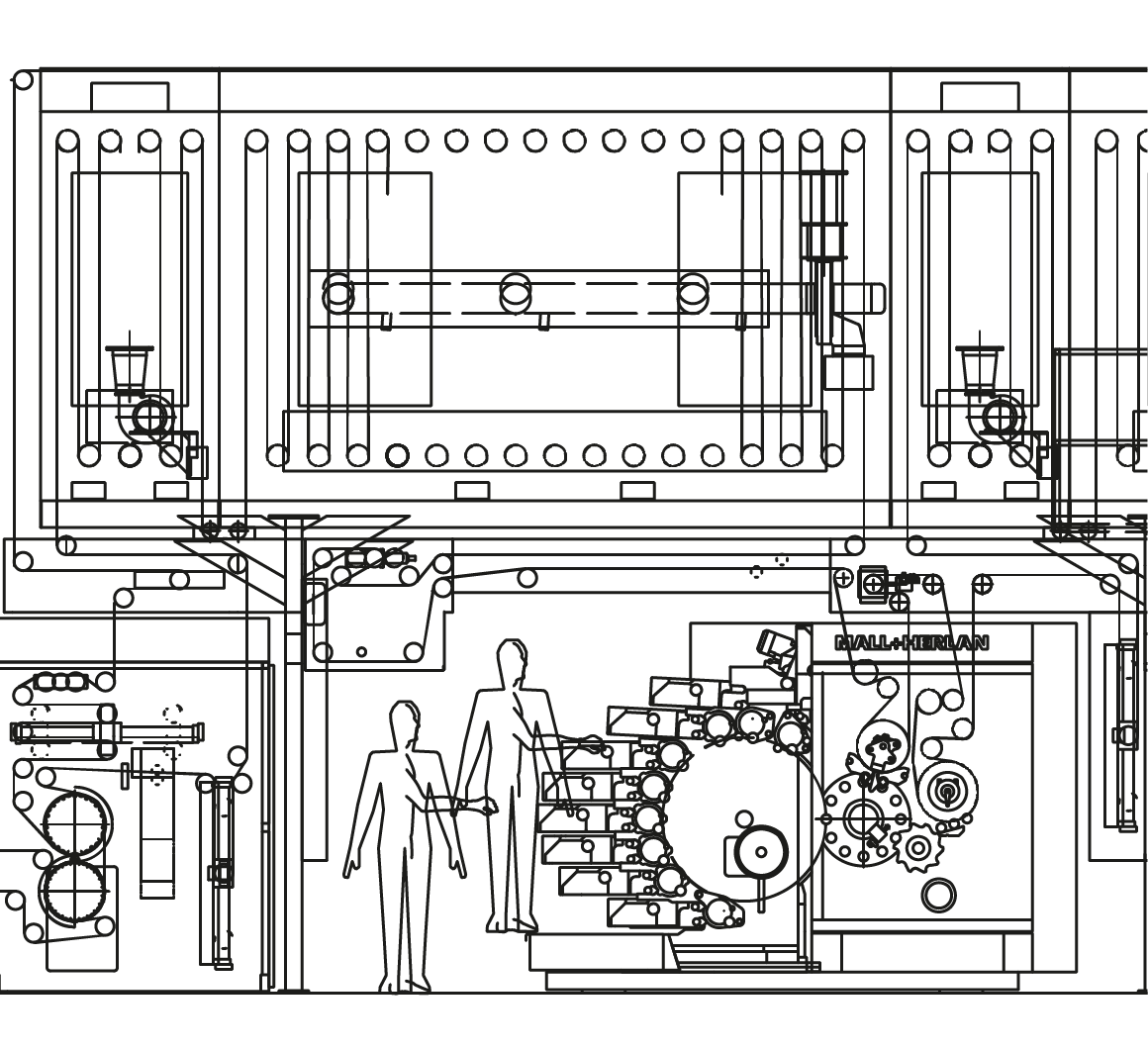

Backed up by over 100 years of expertise and dozens of global installations the mall//herlan TMC tube line stands for a proven and reliable technology. The line consists of three modules: the front-end produces the tubes, the decoration area applies the protective coating and the printing and in the back-end the caps are applied followed by quality checks and final packing.

TMC Production Lines

An aluminium slug enters at the front, and complete tubes - applied with caps, ready to be filled - leaving the line. With an effective speed of 200 tpm over 60 million tubes can be produced per year.

View TMC line video

TMC 200

If you are looking for the highest possible output and a reliable production process the TMC200 is the line of choice for your production of aluminium tubes.

Packing machine

for automatically packing tubes into cartons

Special features

- Ideal for aluminium tubes

- Synchronous transfer

- Process reliability thanks to intermediate compensator

- Easily adjustable to different diameters

- Tubes can be packed tightly in boxes (horizontally/vertically)

Latexing machine

for latexing the inner tube end with non-inflammable coating material

Special features

- Self-drive via servomotor

- Integrated test tube ejection for quality inspection

- Equipped with the high-end centrifugal gun S-540

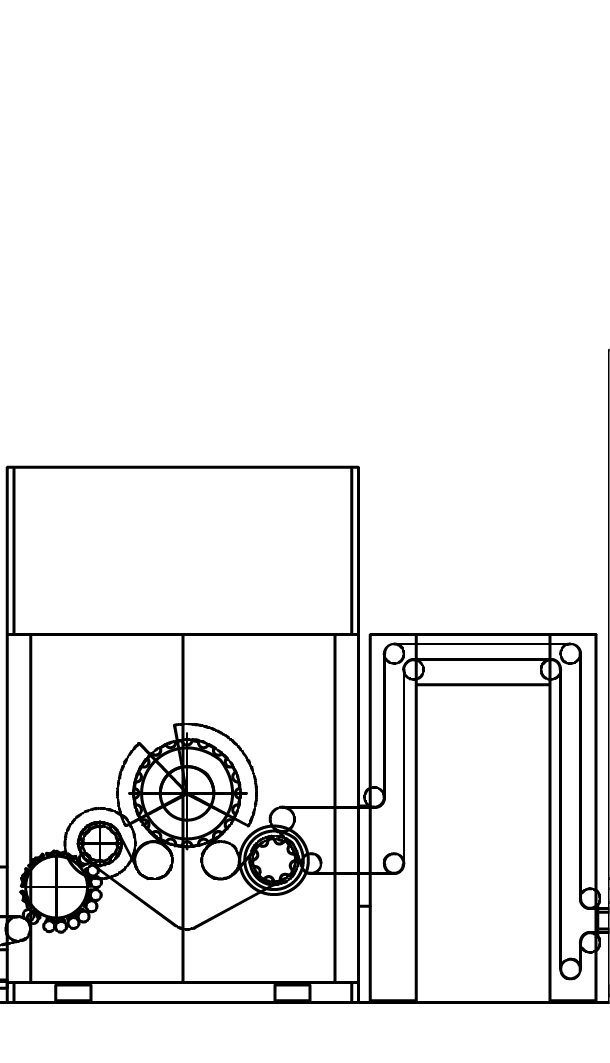

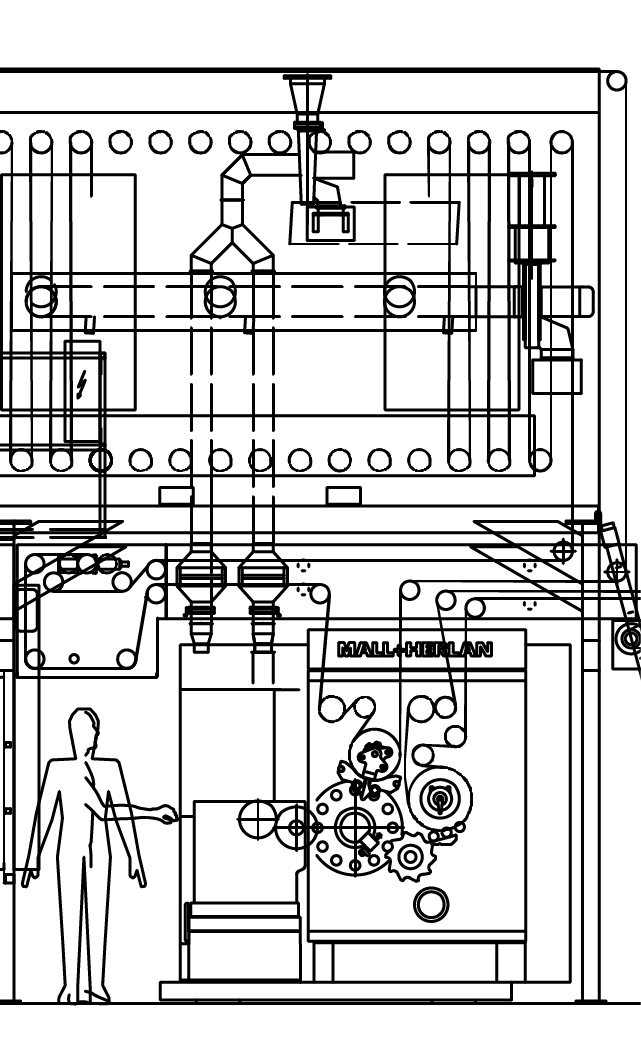

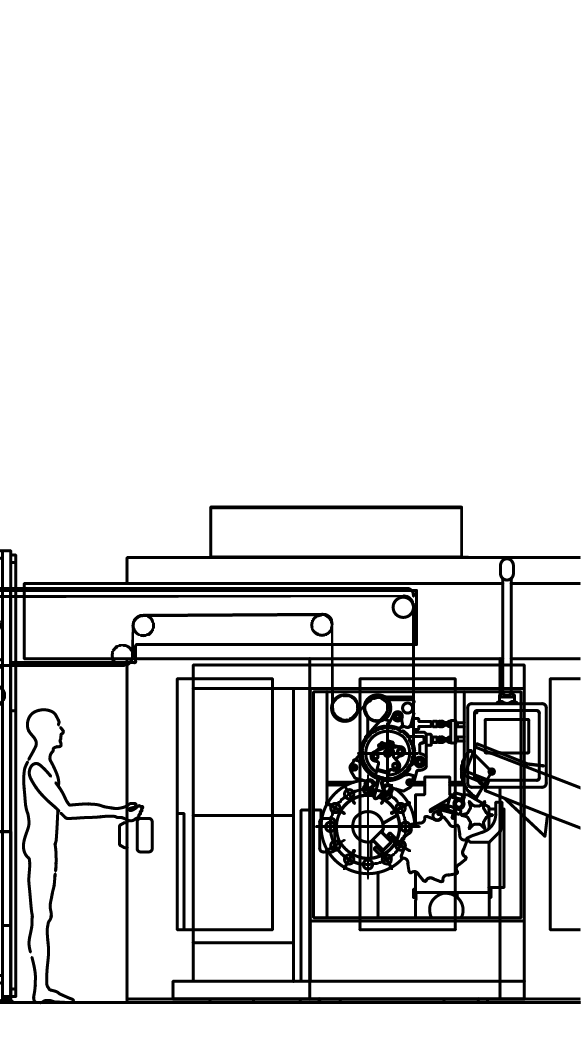

Capping machine

for automatically screwing caps on the tubes

Special features

- Tube transfer from the conveyor chain to a mechanical take-off drum with size-independent vacuum pockets

- Mechanical indexing gear unit with 12 stations

- Mandrel quick change unit and monitoring of the correct clamping

- Vaccum-assited loading and steadying of the tubes on the mandrels, before and during processing

- Two capping stations and one cap tightening station, adjustable on the operator panel

- Transfer unit with two suction units for transporting the tubes from the mandrels onto the chain pins

Accumulator 3

for accumulating the tubes and compensating the asynchronous operation of decoration unit and capping machine.

Special features

- One-part welded frame, mounted onto the floor with a capacity of 1000 cans

- Constant chain tension system

- Safety covering of the accumulator up to a height of 2,5 m with acrylic glass panes at the front side, rear and top with sheet metal covering. A complete covering of the accumulator is optionally available

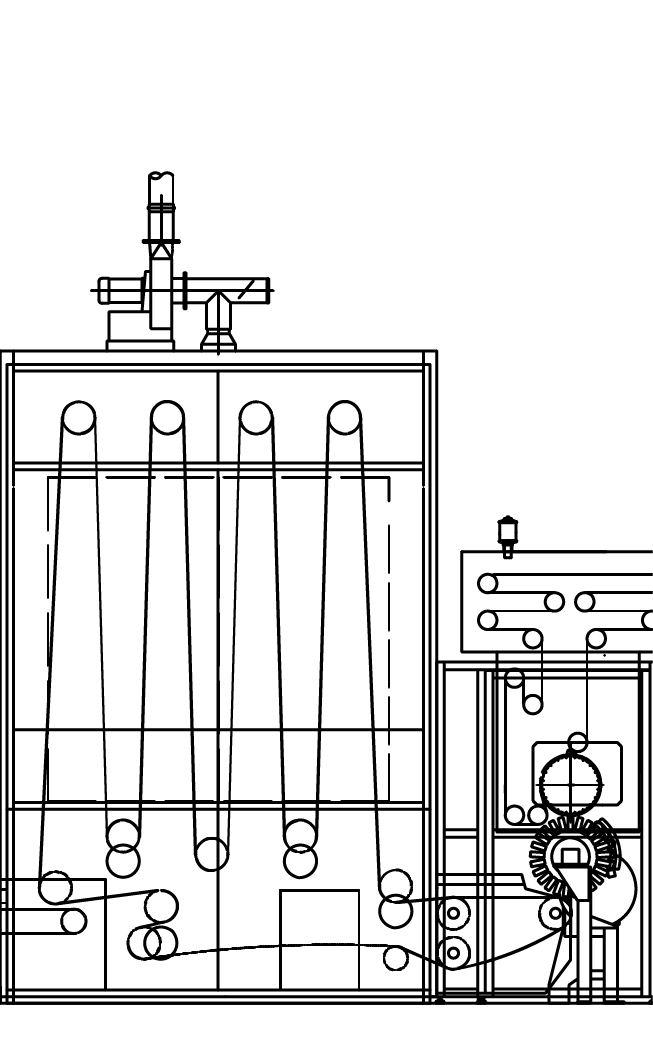

Printing machine

The printing unit, which can apply up to 8 colours, ensures the widest possible decoration variety for aluminium tubes

Special features

- Tube transfer from the conveyor chain to a mechanical take-off drum with size-independent vacuum pockets

- Mechanical indexing gear unit with 12 stations

- Mandrel quick change unit and monitoring of the correct clamping

- Infinitely variable mandrel drive by means of controlled servomotor

- Vacuum-assisted loading and steadying of the tubes on the mandrels, before and during processing

- Printing unit with up to 8 colours

- Transfer unit with take-off control and two suction units for transporting the tubes from the mandrels onto the chain pins

- Oven chamber with integrated chain guide

- Sprocket bearings with re-lubricating facility, installed outside the oven in an aluminium casing sealed towards the rear wall of the oven

- Possibility of tube sampling for test purposes from the pins of the dryer chain, after drying of the printing inks.

Basecoat lacquering

The tube receives the base coat which is important for the stain resistance and excellent print quality. The base coat is dried in the first oven chamber of the decoration drying oven.

Special features 56

- Tube transfer from the conveyor chain to a mechanical take-off drum with size-independent vacuum pockets

- Mechanical indexing gear unit with 12 stations

- Mandrel quick change unit and monitoring of the correct clamping

- Infinitely variable mandrel drive by means of controlled servomotor

- Vacuum-assisted loading and steadying of the tubes on the mandrels, before and during processing

- Three roller base-coating unit designed as V-type-coating unit

- Transfer unit with take-off control and two suction units for transporting the tubes from the mandrels onto the chain pins

- Oven chamber with integrated chain guide

- Sprocket bearings with re-lubricating facility, installed outside the oven in an aluminium casing sealed towards the rear wall of the oven

- Possibility of tube sampling for test purposes from the pins of the dryer chain, after drying of the basecoat

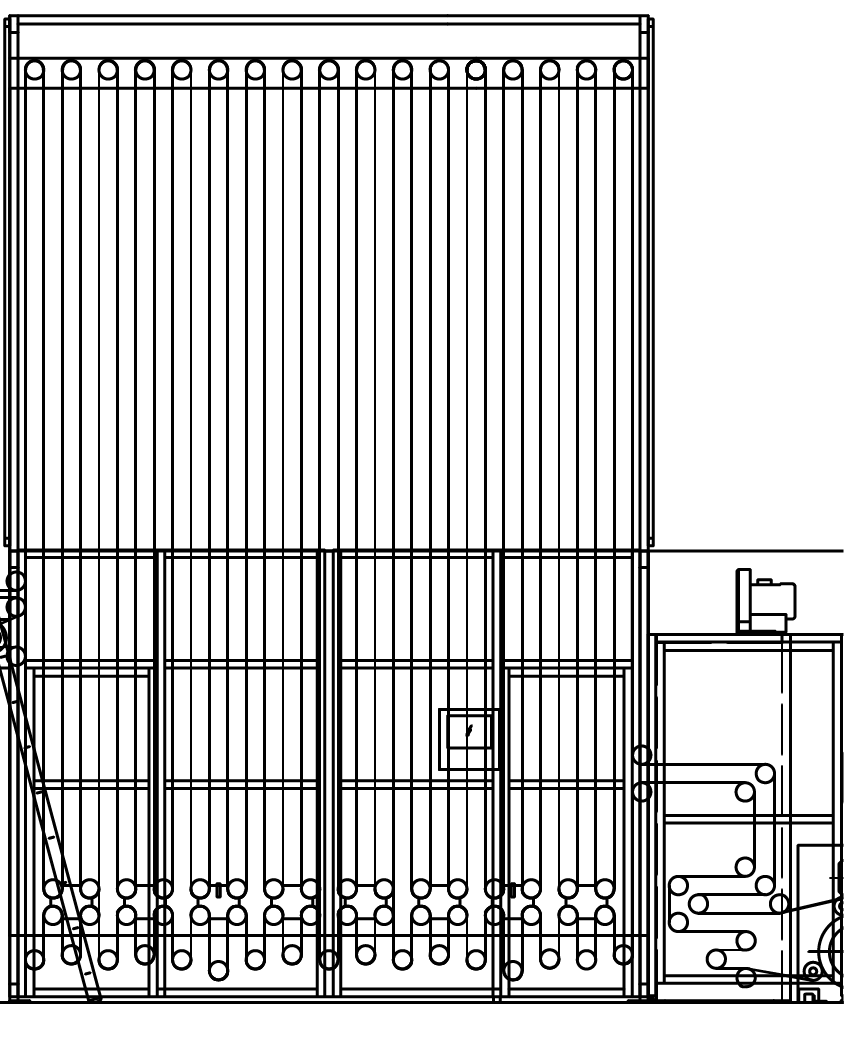

Accumulator 2

for accumulating the tubes and compensating the asynchronous operation of internal coating machine and decoration unit.

Special features

- One-part welded frame, mounted onto the floor with a capacity of 2060 tubes

- Constant chain tension system

- Safety covering of the accumulator up to a height of 2,5 m with acrylic glass panes at the front side, rear and top with sheet metal covering. A complete covering of the accumulator is optionally available

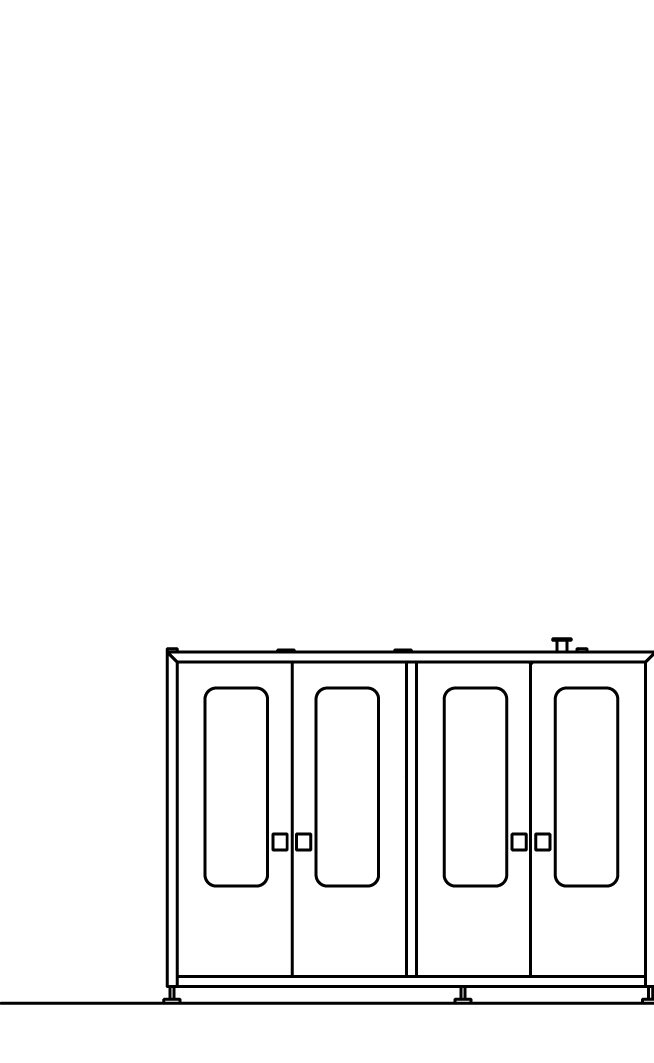

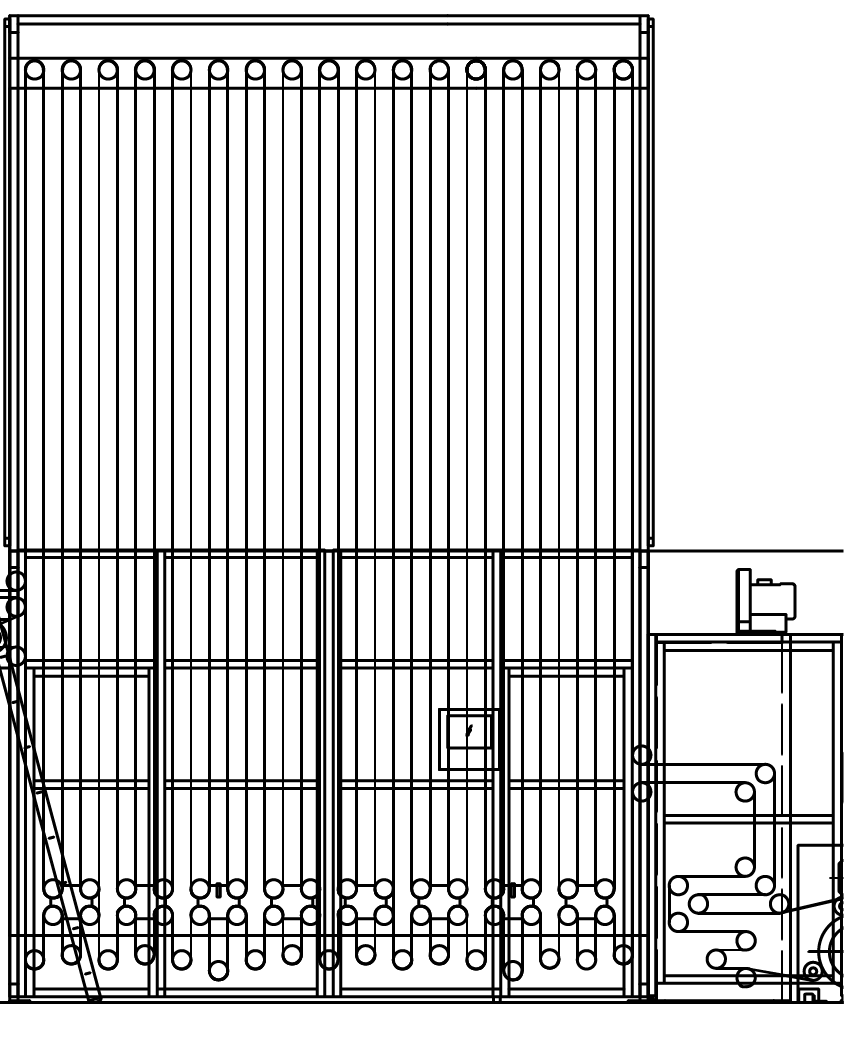

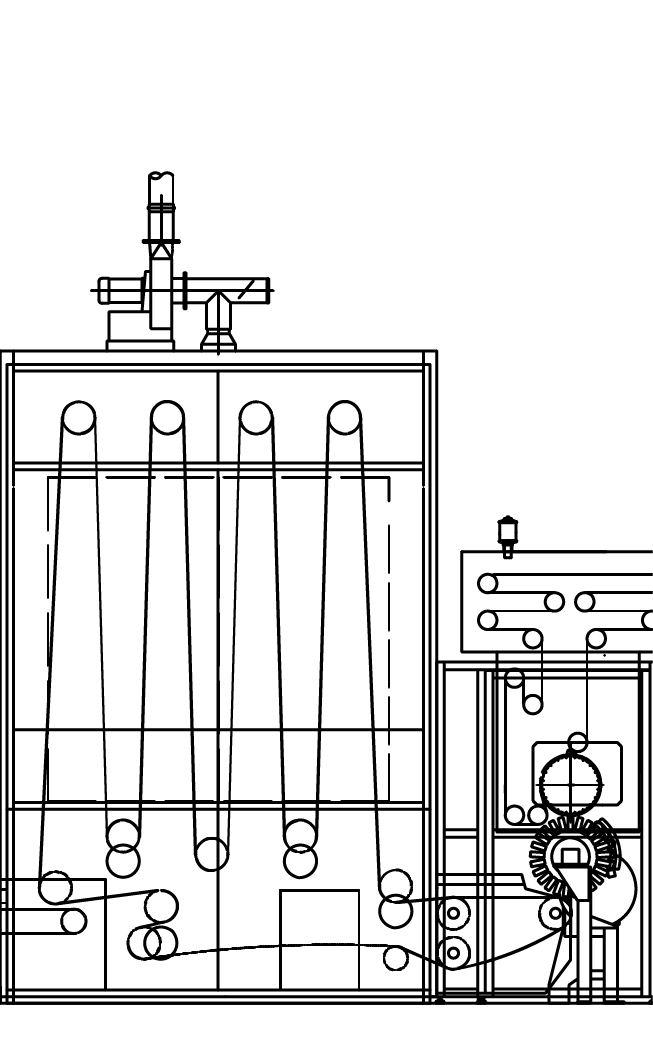

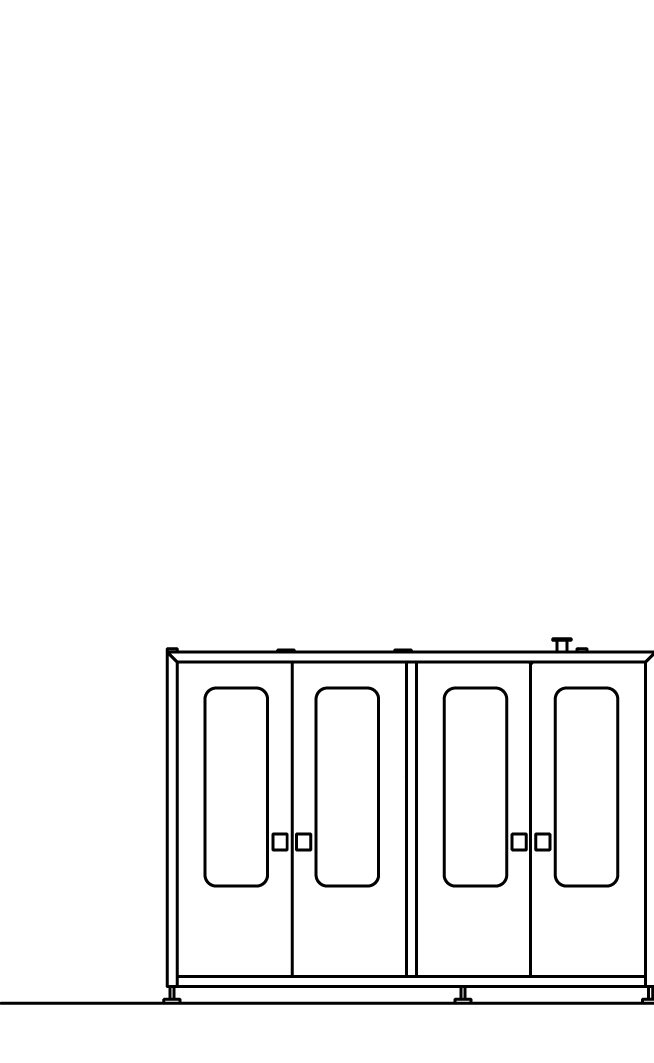

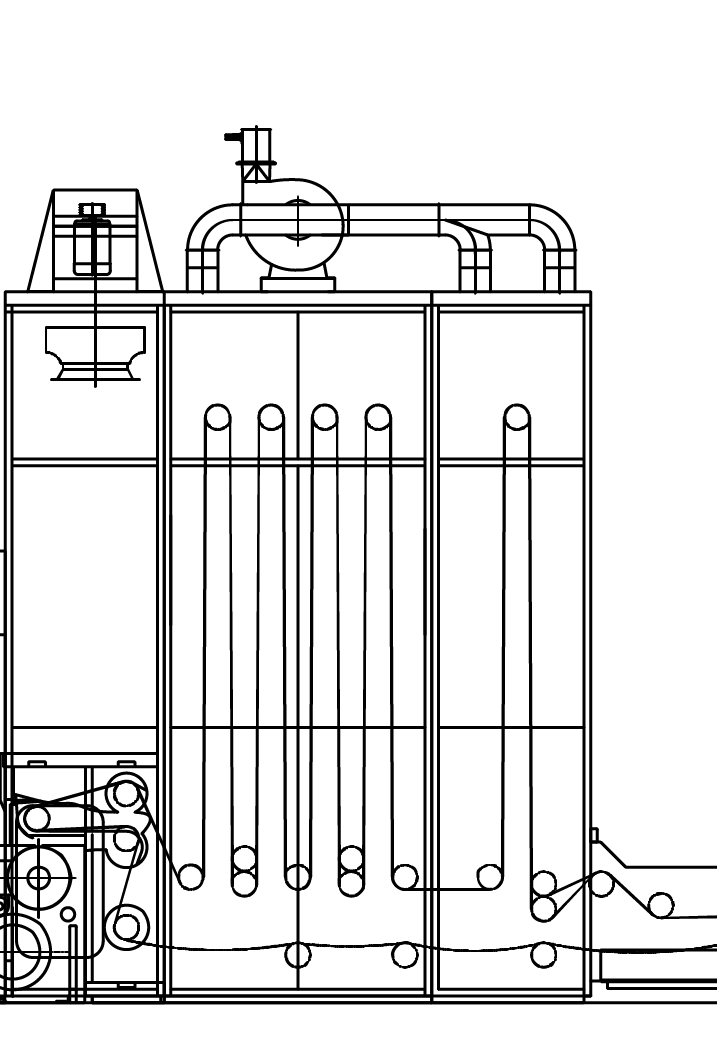

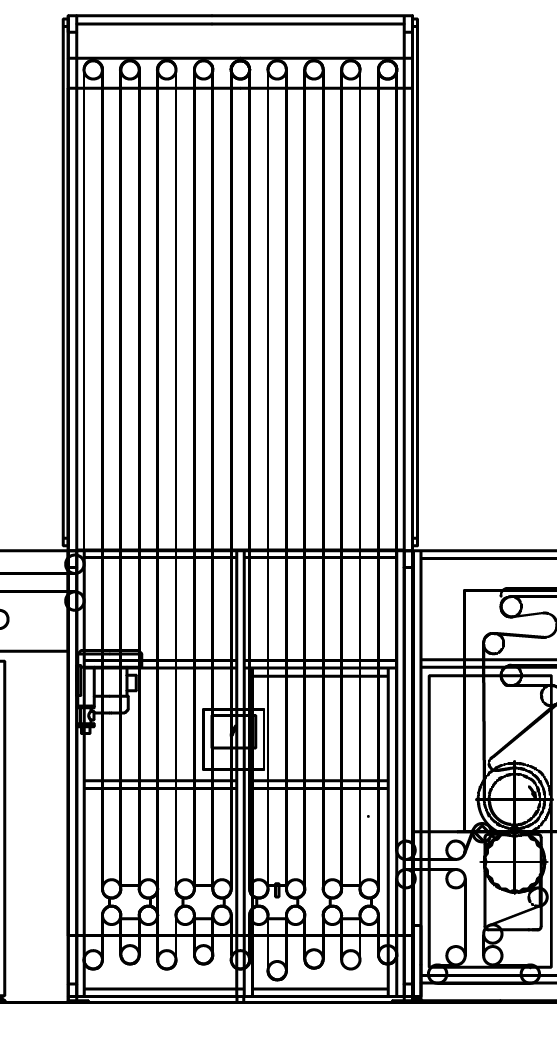

Internal coat dryer

for polymerizing the internal lacquer coat, electrically heated or alternatively by gas.

Special features

- 1 or 2 row transport chain with baskets

- Reduced wear-out of the transport chain and the chain wheels by cardan-based drive system

- Chain tension with weight, electronically monitored

- Easy accessibility to the dryer interior due to large doors

- Quadruple door look

- Isolated doors with special door hinges for synchronized door closing

- Large outer doors with smooth surface on the oven’s front and rear sides

- Quick and easy removal and reassembly of the shafts and chain wheels in case of service

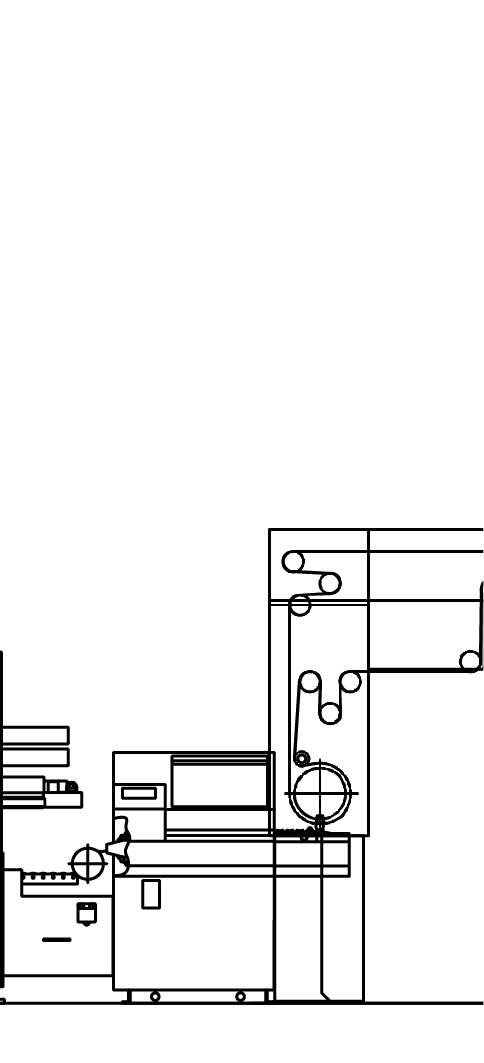

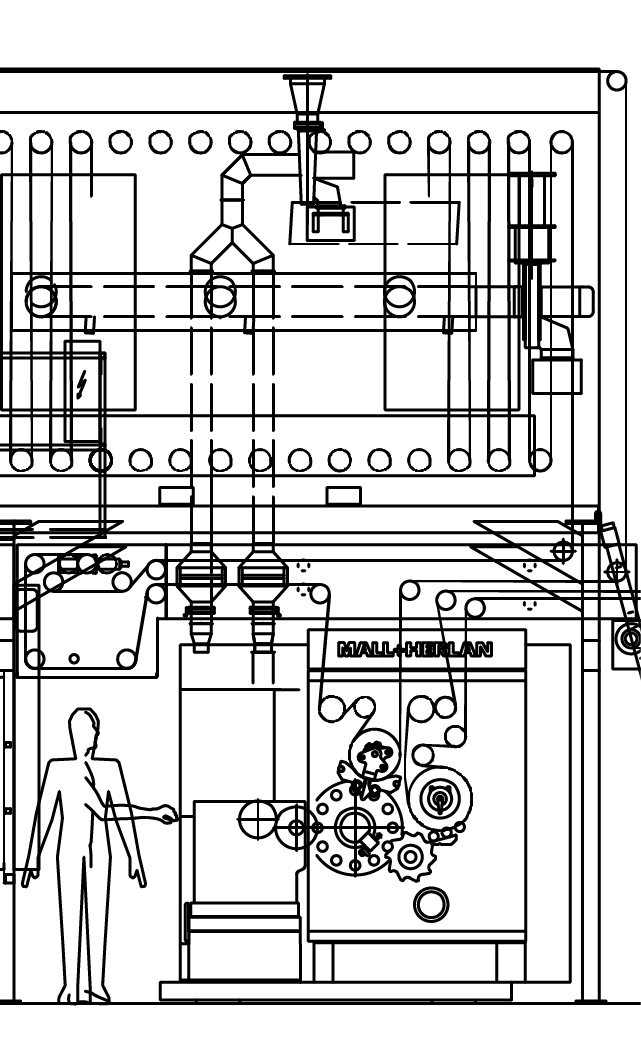

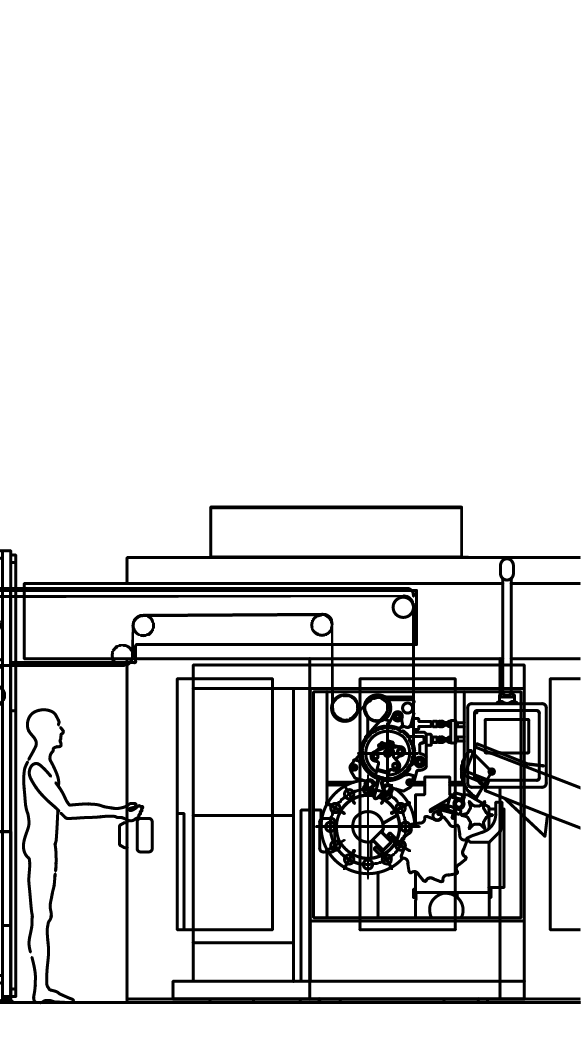

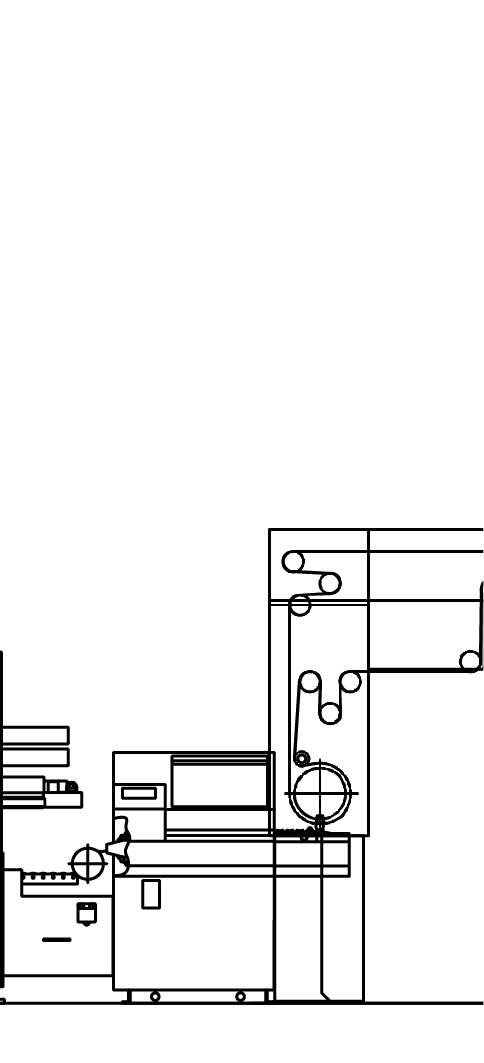

Internal coating machine

A functional lacquer is applied to seal the inside of the tube using moveable spray lances. In the following oven with its cooling zone the inside lacquer is cured and hardened.

Special features

- Low vibration due to solid mechanical design

- Individual vacuum circuit for machine infeed and outfeed

- Increased user comfort by direct electro-pneumatic control of the spray guns by HMI

- Shorter cleaning times by optimized exhaust performance

- Height adjustable and horizontally moveable control panel

- Combinations with different internal coating drier options (1,2 or 3 rows)

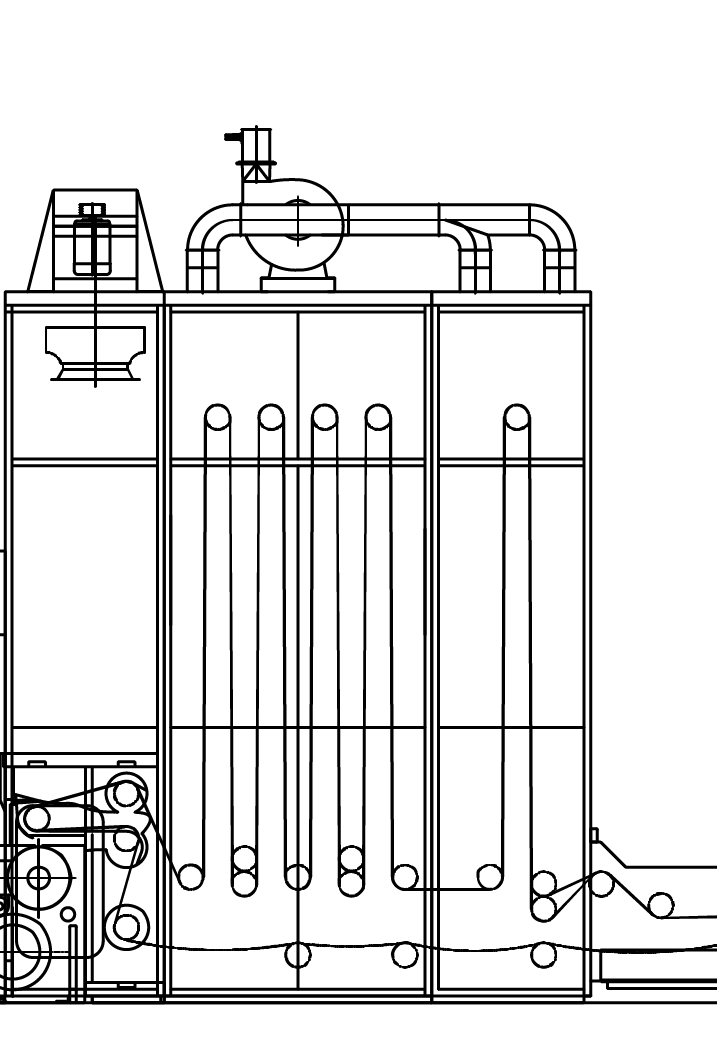

Annealing oven

Electrically or gas heated, for annealing the tubes

Special features

- Transfer of the tubes from the accumulator into the oven

- Double-wall dryer casing with a minimum of fixed connections to avoid thermal bridges

- Inner body of stainless steel

- Smooth and even chain run because of a special design of inner body rear wall

- Big parallel-closing doors with quadruple locking system

- Conveyor chain with trays and chain tighteners

- Automatic conveyor chain lubrication

- Maintenance-free drive system with toothed belts and gear units

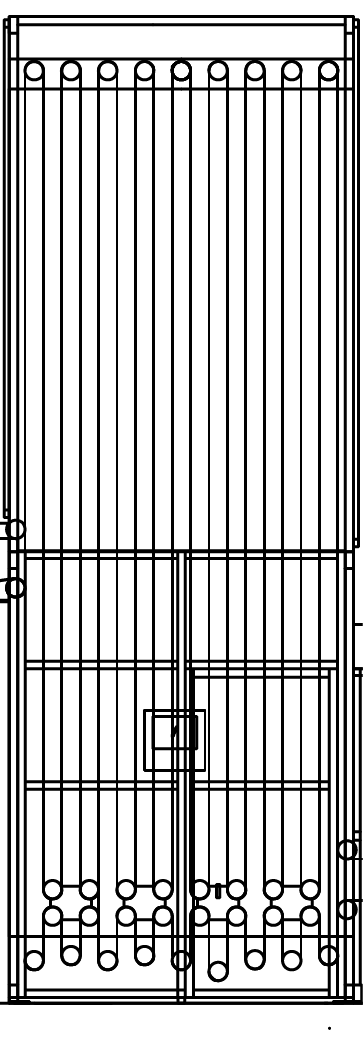

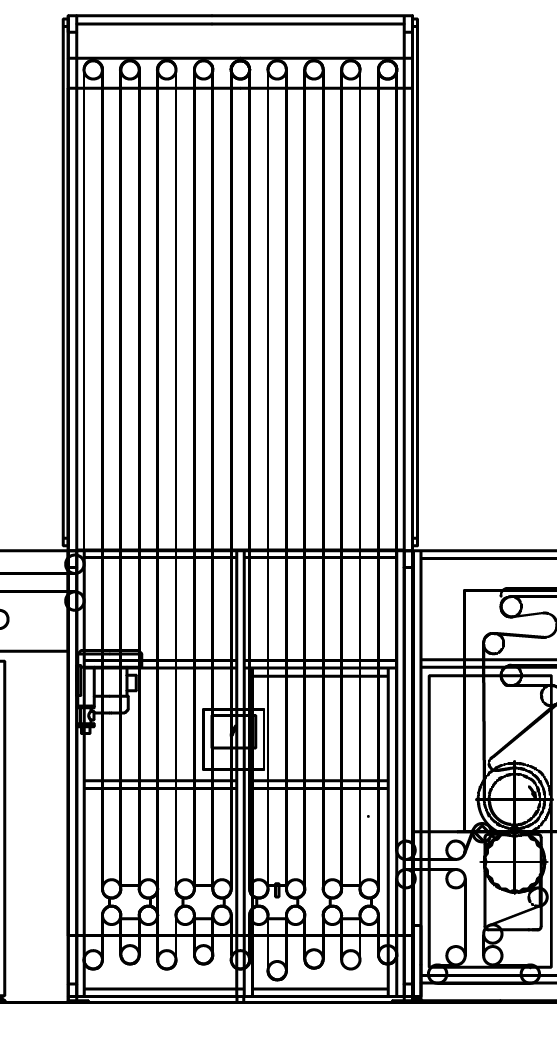

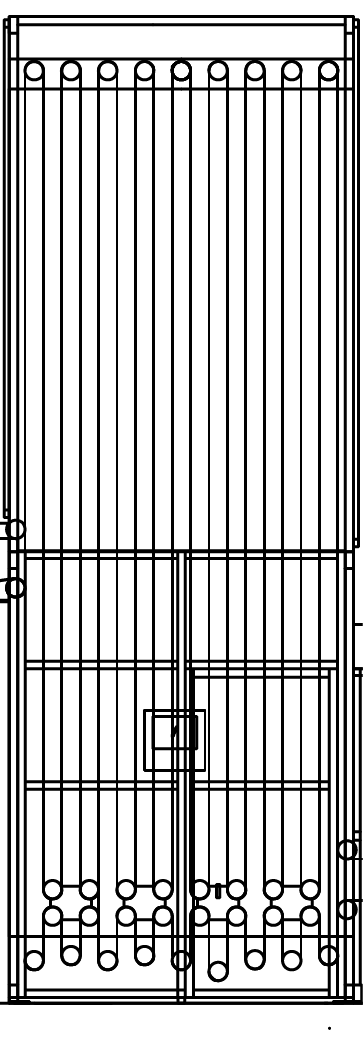

Accumulator 1

for accumulating the tubes and compensating the asynchronous operation of the tube trimmer and annealing oven

Special features

- One-part welded frame, mounted onto the floor with a capacity of 1000 tubes

- Constant chain tension system

- Safety covering of the accumulator up to a height of 2,5 m with acrylic glass panes at the front side, rear and top with sheet metal covering. A complete covering of the accumulator is optionally available

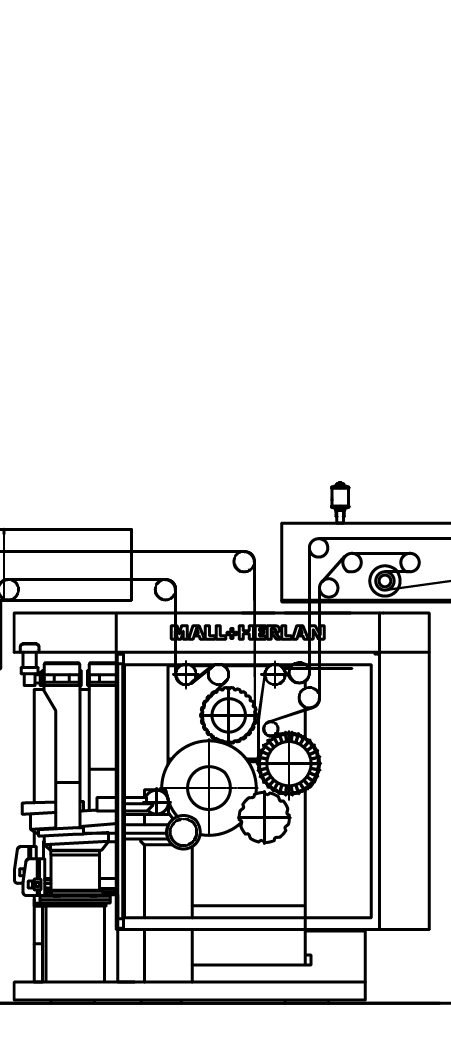

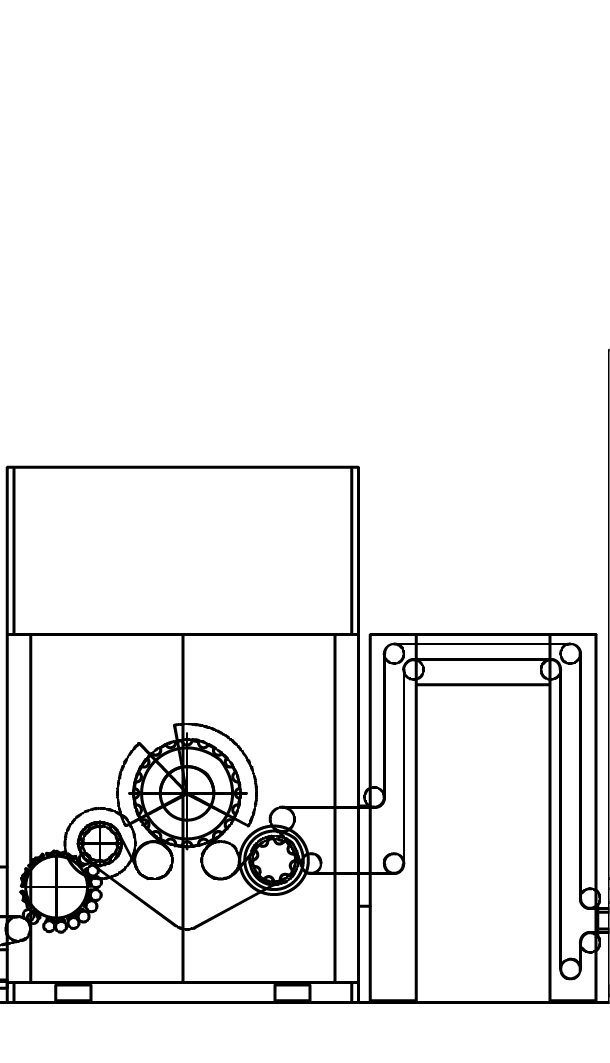

Tube trimmer

The high-performance trimming machines, designed for trimming aluminium preforms to length and for brushing the body, have been fully equipped to allow flawless integration into automatic production lines. When designing the machine, particular importance was attached to ease of operation, quick tool change, easy access, solid process technology, high operational safety and little maintenance.

Technical data

| Type | T10 | MHT |

|---|---|---|

| Tube diameter (mm) | 10-50 | 12,5-55 |

| Max. extruded overall tube length (mm) | 220 | 220/250 |

| Min/max. finished wall length (mm) | 50/210 | 50/240 |

| Assumed wall thickness of tubes (mm) | 0,1 - 0,5 | 0,1 - 0,5 |

Special features T10:

- 10-station turret head with expanding mandrels and mandrel quick-change device

- Unit for pushing the tube onto the mandrel in 2 steps

- Trimming station to cut the tubes to length complete with special tools

- Thread rolling unit for both radial and axial thread rolling

- Shoulder brushing unit for polishing the tube shoulder

- Turning station for finishing the tube neck

- Centered chipless deburring device for the tube orifice

- Swarf suction unit

- Transport systems for the automatic feed and discharge of the tubes

- Protective cover with electrically monitored doors

Special features MHT:

- One.mandrel trimming system: separate trimming station with patented shearing system, scrap ring chopped up on the mandrel and sucked off

- Radial thread rolling unit, with indexed thread rollers

- Tube milling station and shoulder brushing unit, additionally driven for yielding optimum processing speeds

- Swarf suction unit for the tube milling station and the shoulder brushing unit

- Device for deburring the tube orifice

- Unit for smoothing the tube end

- Digital displays for reproducible settings on all tools

- Mandrel drive by means of servomotor, speed-dependent and adjustable

- Expanding mandrel fixture

- Removal of the tubes from the mandrels and discharge onto the continuously operating pin chain

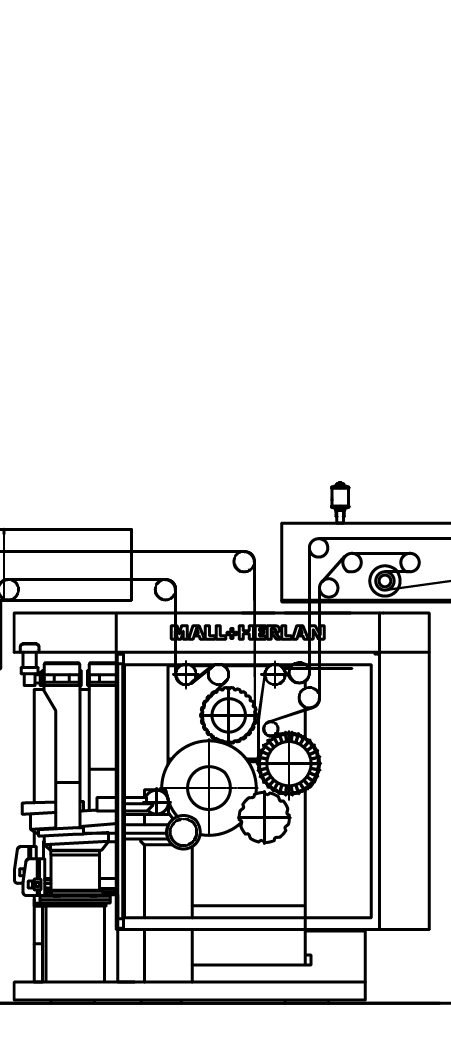

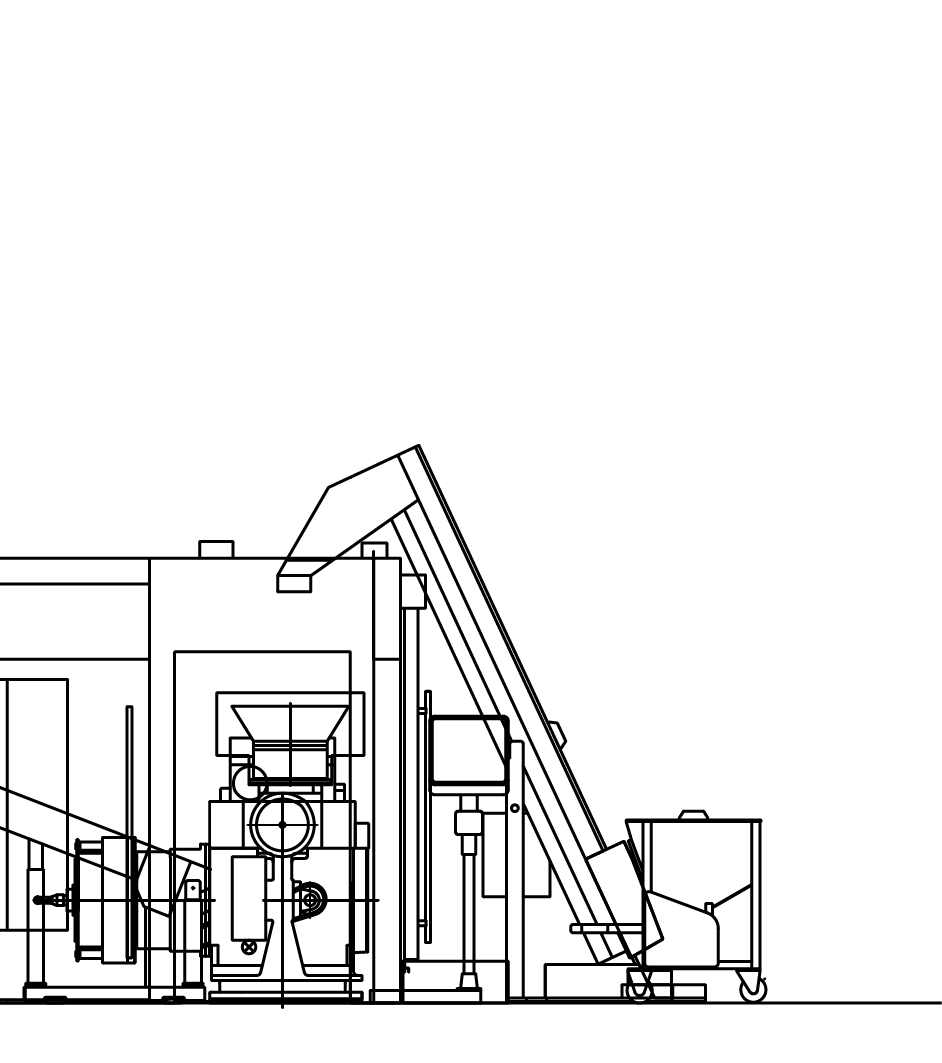

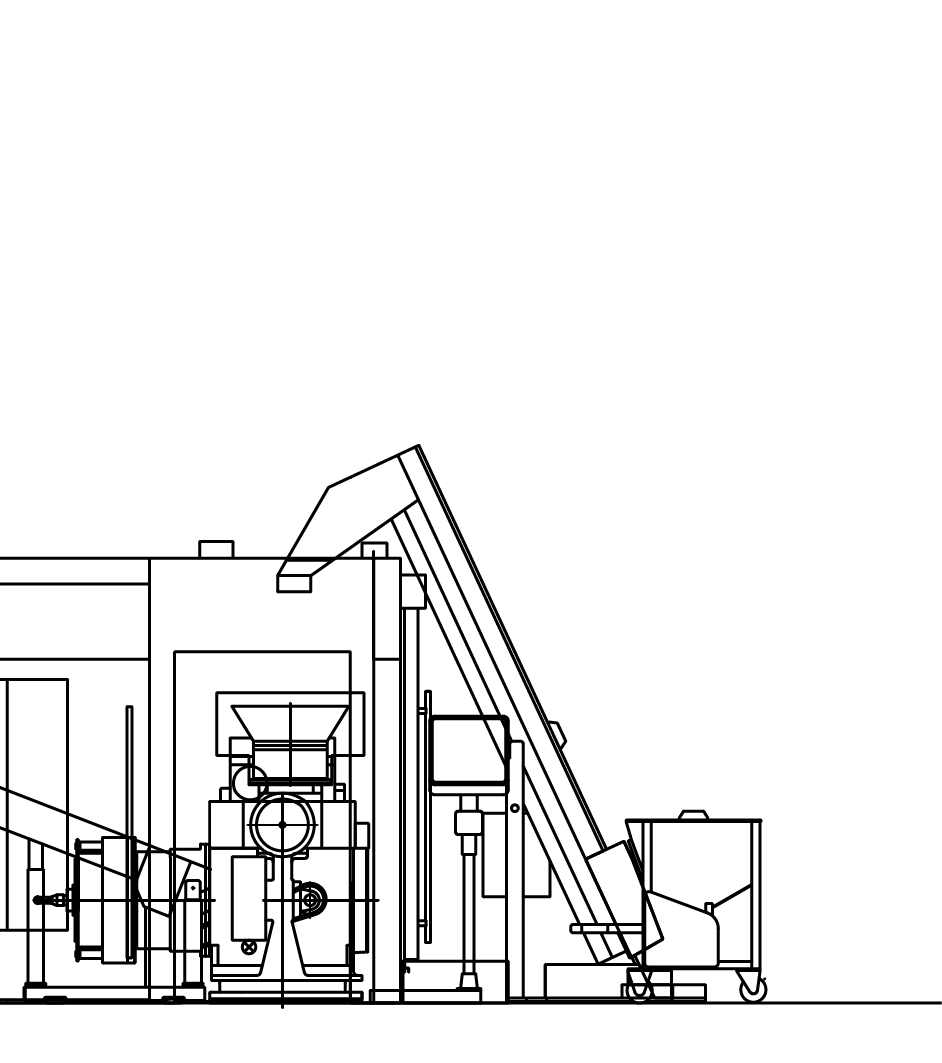

Press

If flexibility is required when producing an aluminium tube, an Impact Extrusion Press is the first choice. A high performance toggle lever system produces aluminium tubes with one stroke out of a slug. As a market leader, our presses are used all over the world for the production of aluminium tubes.

Technical data

| Type | CP35 | CP55 | CP65 |

|---|---|---|---|

| Can diameter (mm) | 10-30 | 19-45 | 25-45 |

| Max. extruded can length (mm) | 130 | 170 | 200 |

| Approx. wall thickness (mm) | 0,3 | 0,3 | 0,4 |

| Nominal press force (kN) | 800 | 1.400 | 1.600 |

Special features

- Sturdy frame, separate from the drive housing, for absorbing the extrusion loads; both parts made of spheroidal graphite iron

- Compact drive of the crankshaft via pneumatically controlled clutch-brake unit with spring loaded disc brake to allow controlled or immediate stops

- Speed-variable drive, creeping speed and facility for switching to reverse motion to facilitate the setting of the tooling

- Electromotive punch adjustment for correcting the bottom thickness during production

- Swing-off type slug feed and stripper frame of the take-off unit, resulting in short set-up times and simple size-part changes, optimized for high speed production

- Automatic permanent circulatory lubrication system with filter and offline filter system

- Take-off unit operating in absolute synchronism with the outfeed conveyor, ensuring trouble-free transfer of the products even in case of short extrusions and maximum stroke rates

- Inclined slug conveyor for direct feed of flat and domed slugs to the die

- Continuous rotary slug infeed system

TMC 170

This line offers the best price-performance ratio if according to the tube design the speed is limited to 170 tpm.

Packing machine

for automatically packing tubes into cartons

Special features

- Ideal for aluminium tubes

- Synchronous transfer

- Process reliability thanks to intermediate compensator

- Easily adjustable to different diameters

- Tubes can be packed tightly in boxes (horizontally/vertically)

Latexing machine

for latexing the inner tube end with non-inflammable coating material

Special features

- Self-drive via servomotor

- Integrated test tube ejection for quality inspection

- Equipped with the high-end centrifugal gun S-540

Capping machine

for automatically screwing caps on the tubes

Special features

- Tube transfer from the conveyor chain to a mechanical take-off drum with size-independent vacuum pockets

- Mechanical indexing gear unit with 12 stations

- Mandrel quick change unit and monitoring of the correct clamping

- Vaccum-assited loading and steadying of the tubes on the mandrels, before and during processing

- Two capping stations and one cap tightening station, adjustable on the operator panel

- Transfer unit with two suction units for transporting the tubes from the mandrels onto the chain pins

Accumulator 3

for accumulating the tubes and compensating the asynchronous operation of decoration unit and capping machine.

Special features

- One-part welded frame, mounted onto the floor with a capacity of 500 cans

- Constant chain tension system

- Safety covering of the accumulator up to a height of 2,5 m with acrylic glass panes at the front side, rear and top with sheet metal covering. A complete covering of the accumulator is optionally available

Printing machine

The printing unit, which can apply up to 8 colours, ensures the widest possible decoration variety for aluminium tubes

Special features

- Tube transfer from the conveyor chain to a mechanical take-off drum with size-independent vacuum pockets

- Mechanical indexing gear unit with 12 stations

- Mandrel quick change unit and monitoring of the correct clamping

- Infinitely variable mandrel drive by means of controlled servomotor

- Vacuum-assisted loading and steadying of the tubes on the mandrels, before and during processing

- Printing unit with up to 8 colours

- Transfer unit with take-off control and two suction units for transporting the tubes from the mandrels onto the chain pins

- Oven chamber with integrated chain guide

- Sprocket bearings with re-lubricating facility, installed outside the oven in an aluminium casing sealed towards the rear wall of the oven

- Possibility of tube sampling for test purposes from the pins of the dryer chain, after drying of the printing inks.

Basecoat lacquering

The tube receives the base coat which is important for the stain resistance and excellent print quality. The base coat is dried in the first oven chamber of the decoration drying oven.

Special features

- Tube transfer from the conveyor chain to a mechanical take-off drum with size-independent vacuum pockets

- Mechanical indexing gear unit with 12 stations

- Mandrel quick change unit and monitoring of the correct clamping

- Variable mandrel drive by means of controlled servomotor

- Vacuum-assisted loading and steadying of the tubes on the mandrels, before and during processing

- Three roller base-coating unit designed as V-type-coating unit

- Transfer unit with take-off control and two suction units for transporting the tubes from the mandrels onto the chain pins

- Oven chamber with integrated chain guide

- Sprocket bearings with re-lubricating facility, installed outside the oven in an aluminium casing sealed towards the rear wall of the oven

- Possibility of tube sampling for test purposes from the pins of the dryer chain, after drying of the basecoat

Accumulator 2

for accumulating the tubes and compensating the asynchronous operation of internal coating machine and decoration unit.

Special features

- One-part welded frame, mounted onto the floor with a capacity of up to 2000 tubes

- Constant chain tension system

- Safety covering of the accumulator up to a height of 2,5 m with acrylic glass panes at the front side, rear and top with sheet metal covering. A complete covering of the accumulator is optionally available

Internal coat dryer

for polymerizing the internal lacquer coat, electrically heated or alternatively by gas.

Special features

- 1 or 2 row transport chain with baskets

- Reduced wear-out of the transport chain and the chain wheels by cardan-based drive system

- Chain tension with weight, electronically monitored

- Easy accessibility to the dryer interior due to large doors

- Quadruple door look

- Isolated doors with special door hinges for synchronized door closing

- Large outer doors with smooth surface on the oven’s front and rear sides

- Quick and easy removal and reassembly of the shafts and chain wheels in case of service

Internal coating machine

A functional lacquer is applied to seal the inside of the tube using moveable spray lances. In the following oven with its cooling zone the inside lacquer is cured and hardened.

Special features

- Low vibration due to solid mechanical design

- Individual vacuum circuit for machine infeed and outfeed

- Increased user comfort by direct electro-pneumatic control of the spray guns by HMI

- Shorter cleaning times by optimized exhaust performance

- Height adjustable and horizontally moveable control panel

- Combinations with different internal coating drier options (1,2 or 3 rows)

Annealing oven

Electrically or gas heated, for annealing the tubes

Special features

- Transfer of the tubes from the accumulator into the oven

- Double-wall dryer casing with a minimum of fixed connections to avoid thermal bridges

- Inner body of stainless steel

- Smooth and even chain run because of a special design of inner body rear wall

- Big parallel-closing doors with quadruple locking system

- Conveyor chain with trays and chain tighteners

- Automatic conveyor chain lubrication

- Maintenance-free drive system with toothed belts and gear units

Accumulator 1

for accumulating the tubes and compensating the asynchronous operation of the tube trimmer and annealing oven

Special features

- One-part welded frame, mounted onto the floor with a capacity of 500 tubes

- Constant chain tension system

- Safety covering of the accumulator up to a height of 2,5 m with acrylic glass panes at the front side, rear and top with sheet metal covering. A complete covering of the accumulator is optionally available

Tube trimmer

The long-establised trimming machines, designed for trimming aluminium preforms to length and for brushing the body, have been fully equipped to allow flawless integration into automatic production lines.

Technical data

| Type | T10 |

|---|---|

| Tube diameter (mm) | 10-50 |

| Max. extruded overall tube length (mm) | 220 |

| Min/max. finished wall length (mm) | 50/210 |

| Assumed wall thickness of tubes (mm) | 0,1 - 0,5 |

Special features T10:

- 10-station turret head with expanding mandrels and mandrel quick-change device

- Unit for pushing the tube onto the mandrel in 2 steps

- Trimming station to cut the tubes to length complete with special tools

- Thread rolling unit for both radial and axial thread rolling

- Shoulder brushing unit for polishing the tube shoulder

- Turning station for finishing the tube neck

- Centered chipless deburring device for the tube orifice

- Swarf suction unit

- Transport systems for the automatic feed and discharge of the tubes

- Protective cover with electrically monitored doors

Press

If flexibility is required when producing an aluminium tube, an Impact Extrusion Press is the first choice. A high performance toggle lever system produces aluminium tubes with one stroke out of a slug. As a market leader, our presses are used all over the world for the production of aluminium tubes.

Technical data

| Type | CP35 | CP55 | CP65 |

|---|---|---|---|

| Can diameter (mm) | 10-30 | 19-45 | 25-45 |

| Max. extruded can length (mm) | 130 | 170 | 200 |

| Approx. wall thickness (mm) | 0,3 | 0,3 | 0,4 |

| Nominal press force (kN) | 800 | 1.400 | 1.600 |

Special features

- Sturdy frame, separate from the drive housing, for absorbing the extrusion loads; both parts made of spheroidal graphite iron

- Compact drive of the crankshaft via pneumatically controlled clutch-brake unit with spring loaded disc brake to allow controlled or immediate stops

- Speed-variable drive, creeping speed and facility for switching to reverse motion to facilitate the setting of the tooling

- Electromotive punch adjustment for correcting the bottom thickness during production

- Swing-off type slug feed and stripper frame of the take-off unit, resulting in short set-up times and simple size-part changes, optimized for high speed production

- Automatic permanent circulatory lubrication system with filter and offline filter system

- Take-off unit operating in absolute synchronism with the outfeed conveyor, ensuring trouble-free transfer of the products even in case of short extrusions and maximum stroke rates

- Inclined slug conveyor for direct feed of flat and domed slugs to the die

- Continuous rotary slug infeed system

Markets

Aluminium tubes are a growing market with excellent prospects for the future. The trends towards placing greater importance on packing solutions of greater quality, uniqueness and sustainabilty can be recognized across a wide range of industries. mall//herlan serves the following industries with it's lines for aluminium tube production:

- Cosmetics and health care

- Pharma

- Food

- Technical products